310 Stainless Steel – Premium Heat-Resistant Austenitic Alloy for Continuous 1100 °C Performance

310 Stainless Steel is the austenitic powerhouse engineered for the most punishing thermal cycles on earth. With 24–26 % chromium and 19–22 % nickel balanced at ≤0.25 % carbon, UNS S31000 forms a dense, self-healing oxide that withstands continuous 1100 °C and intermittent 1150 °C while competitors scale away. The grade offers twice the oxidation life of 309, four times that of 304, and creep-rupture strength that keeps furnace fixtures from sagging after 10 000 hours at 900 °C. Whether you are lining a direct-fired kiln, fabricating radiant heater tubes or building an aerospace after-burner duct, 310 Stainless Steel delivers the high-temperature integrity that keeps production—and profits—running hot.

Key Features & Benefits – Why 310 Stainless Steel Thrives When the Thermometer Hits Red

Outstanding Oxidation & Scaling Resistance

- Parabolic scaling rate < 0.05 mm/year at 1000 °C—half that of 309 and one-quarter of 304, doubling component life.

- Chromium oxide layer regenerates in low-oxygen atmospheres, protecting carburising and sulfidising environments up to 1050 °C.

High Creep & Rupture Strength

- 100 000 h rupture stress at 900 °C is 45 MPa—70 % higher than 316, allowing thinner radiant tubes and lighter load on supports.

Excellent Thermal Fatigue & Shock Tolerance

- Coefficient of expansion 15.9 µm/m·K (20–1000 °C) balances thermal growth, reducing distortion in cyclically fired muffles.

- Retains 35 % elongation after 1 000 thermal cycles 20–1000 °C—ideal for kiln cars and reciprocating grates.

Moderate Aqueous Corrosion Resistance

- 24 % Cr passive film handles mild acids and atmospheric exposure; ASTM B117 salt-spray > 500 h with <2 % rust area.

Good Weldability Without Post-Weld Sensitisation

- Low carbon plus high chromium minimise chromium-carbide formation; welded joints pass ASTM A262 Practice E without fissures.

Cost-Effective Upgrade Path

- Priced 20 % above 309 but 40 % below nickel alloys 600 or 625, offering the lowest cost per hour of high-temperature service.

Technical Specifications

| Property | Value | Standard |

|---|---|---|

| Density | 7.9 g/cm³ | ASTM A240 |

| Melting Range | 1 400 – 1 450 °C | ASTM A479 |

| Tensile Strength (RT) | ≥ 515 MPa | ASTM A370 |

| Yield Strength (RT) | ≥ 205 MPa | ASTM A370 |

| Elongation | ≥ 40 % | ASTM A370 |

| Hardness, HRB | ≤ 95 | ASTM E18 |

| Max Continuous Temp | 1100 °C | ASTM G54 |

| Max Intermittent Temp | 1150 °C | ASTM G54 |

Values meet UNS S31000, AISI 310, EN 1.4845 and ASTM A276/A479, ensuring global code acceptance.

Applications & Use Cases – Proven Survivability from Furnace Floors to Jet Exhaust

Furnace Components – Muffles, Retorts, Hearth Plates

310 Stainless Steel withstands direct flame impingement in bright-annealing furnaces. A European heat-treater extended muffle life from 18 to 42 months after upgrading from 309, saving €300 000 in downtime.

Kiln & Oven Hardware

Car-bottom kiln rails and roller hearths operate at 1050 °C with loads up to 5 kN/m; 310’s creep strength prevents sagging, maintaining tray flatness ±1 mm over 30 m length.

Radiant Tubes & Heater Elements

Electric and gas-fired tubes at 1000 °C radiate heat to metal billets; 310 Stainless Steel tubes show 0.03 mm oxide growth after 8 000 h versus 0.12 mm for 304.

Petrochemical Cracking & Reforming

Ethylene furnace coils handle 850 °C process gas plus steam; 310’s sulfidation resistance outperforms 316, doubling run length between decokes.

Power Plant Boiler & Super-heater Tubes

310 Stainless Steel supports 600 °C steam/600 bar pressure in advanced ultra-super-critical plants, offering higher allowable stress than 347H above 650 °C.

Aerospace Engine & After-burner Parts

Weight-saving sheet metal ducts and fairings survive 1100 °C exhaust gas; 310’s thermal-fatigue resistance eliminates costly Inconel 625 in non-load regions.

Thermal Processing Baskets & Fixtures

Baskets for carburising gears maintain shape after 500 cycles at 950 °C; 310’s carburisation depth is < 0.05 mm versus 0.3 mm for 304.

Comparison with Other Grades – 310 vs 304, 309, 316, 253MA

| Grade | Cr % | Ni % | Max Cont. Temp °C | Oxidation Rating | Relative Cost | Typical Uses |

|---|---|---|---|---|---|---|

| 304 | 18 | 8 | 870 | Good | Medium | Food equipment |

| 309 | 22 | 12 | 1000 | Very Good | Medium+ | Furnace parts |

| 316 | 17 | 10 | 870 | Good | High | Marine chemical |

| 253MA | 21 | 11 | 1150 | Excellent | High+ | High-efficiency kilns |

| 310 | 25 | 20 | 1100 | Excellent | High | Standard high-heat |

Pros: 310 Stainless Steel provides the best oxidation resistance among standard austenitic grades up to 1100 °C without rare-earth alloying premiums.

Cons: For cyclic 1150 °C or sulfur-rich reducing gases, evaluate 253MA or nickel alloys; for marine chloride duty, select 316L.

Manufacturing Process & Quality Assurance

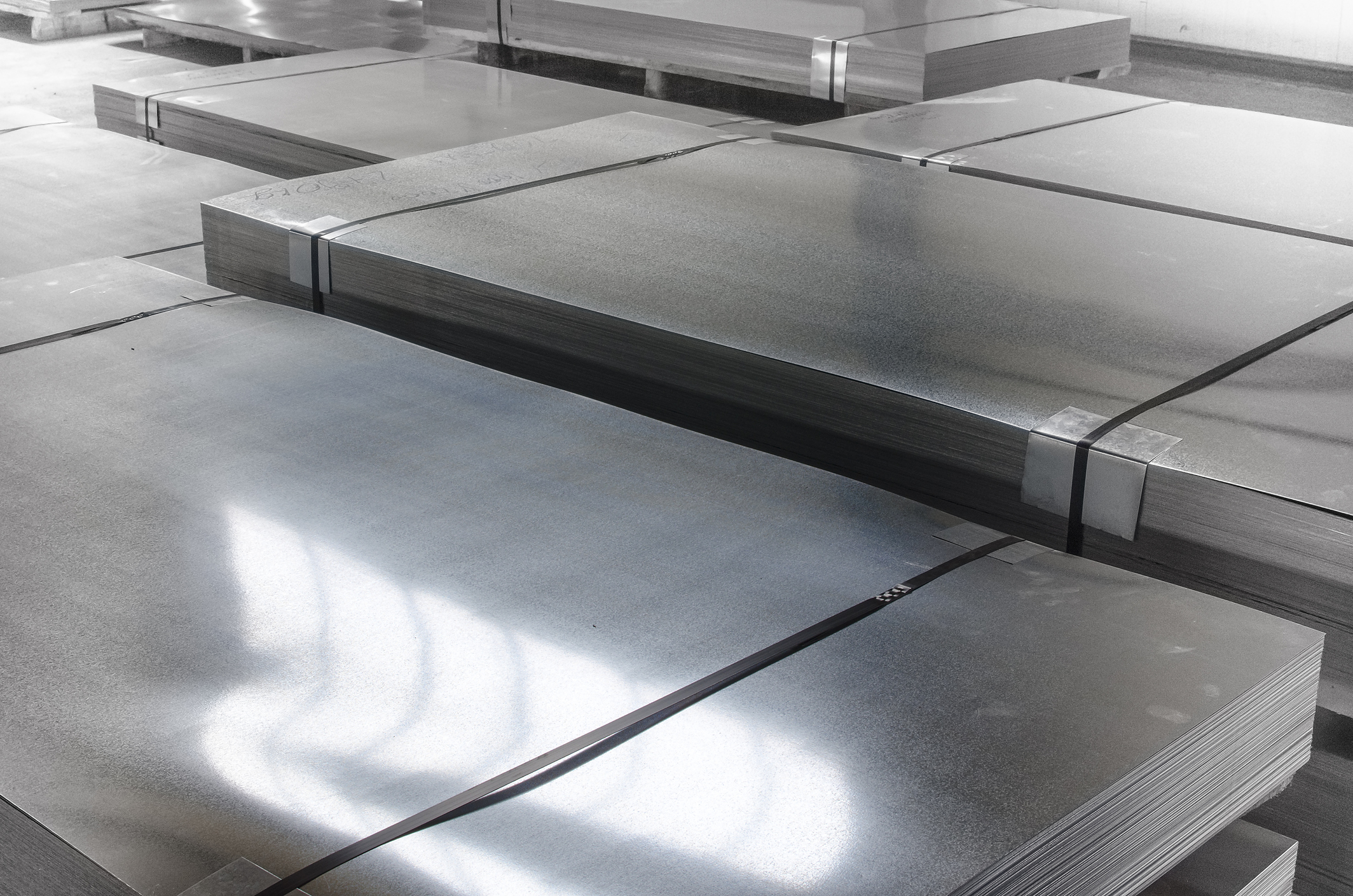

We melt 310 Stainless Steel in an electric-arc furnace, argon-oxygen decarburise to ≤ 0.25 % C, then continuous-cast into 300 mm slabs. Hot rolling to plate or strip is followed by solution annealing at 1030–1180 °C and water quench to dissolve chromium carbides and restore full oxidation resistance. Finishes include No. 1 hot-rolled plate, 2B cold-rolled sheet, and polished Ra ≤ 0.4 µm for aerospace ducts. Every heat is certified to ASTM A240/A479, ISO 9001 and optional EN 10204 3.2; tests include ICP chemistry, elevated-temperature tensile at 900 °C, ASTM G54 cyclic oxidation (200 h at 1100 °C), and grain-size determination. Third-party inspection reports and NORSOK M-650 compliance are available for oil & gas projects.

Maintenance & Care Tips

Clean 310 Stainless Steel with warm water and a neutral detergent; avoid abrasive pads that can embed free iron. For components cycling above 800 °C, annual inspection for oxide spallation is recommended—light brushing and compressed-air blowing restore emissivity. Perform occasional 2 % citric-acid passivation if the surface is contaminated by carbon-steel tools. Store plate and bar indoors, vertically separated by plastic to prevent chloride pick-up from coastal air.

Frequently Asked Questions

Q: What is the maximum operating temperature for 310 Stainless Steel?

A: 1100 °C continuous, 1150 °C intermittent; above this, consider nickel alloys or 253MA.

Q: How does 310 compare to 304 in high-heat environments?

A: 310 offers four times longer oxidation life and double creep strength at 900 °C, making 304 unsuitable beyond 870 °C.

Q: Is 310 Stainless Steel suitable for welding?

A: Yes—low carbon and high chromium prevent sensitisation; use 310 or 309 filler rods and no pre-heat or post-weld anneal is required.

Ready to eliminate high-temperature scaling and costly downtime? Contact us today for custom quotes on 310 Stainless Steel sheet, plate, tube or bar—mill-direct pricing, global delivery and full metallurgical support included.