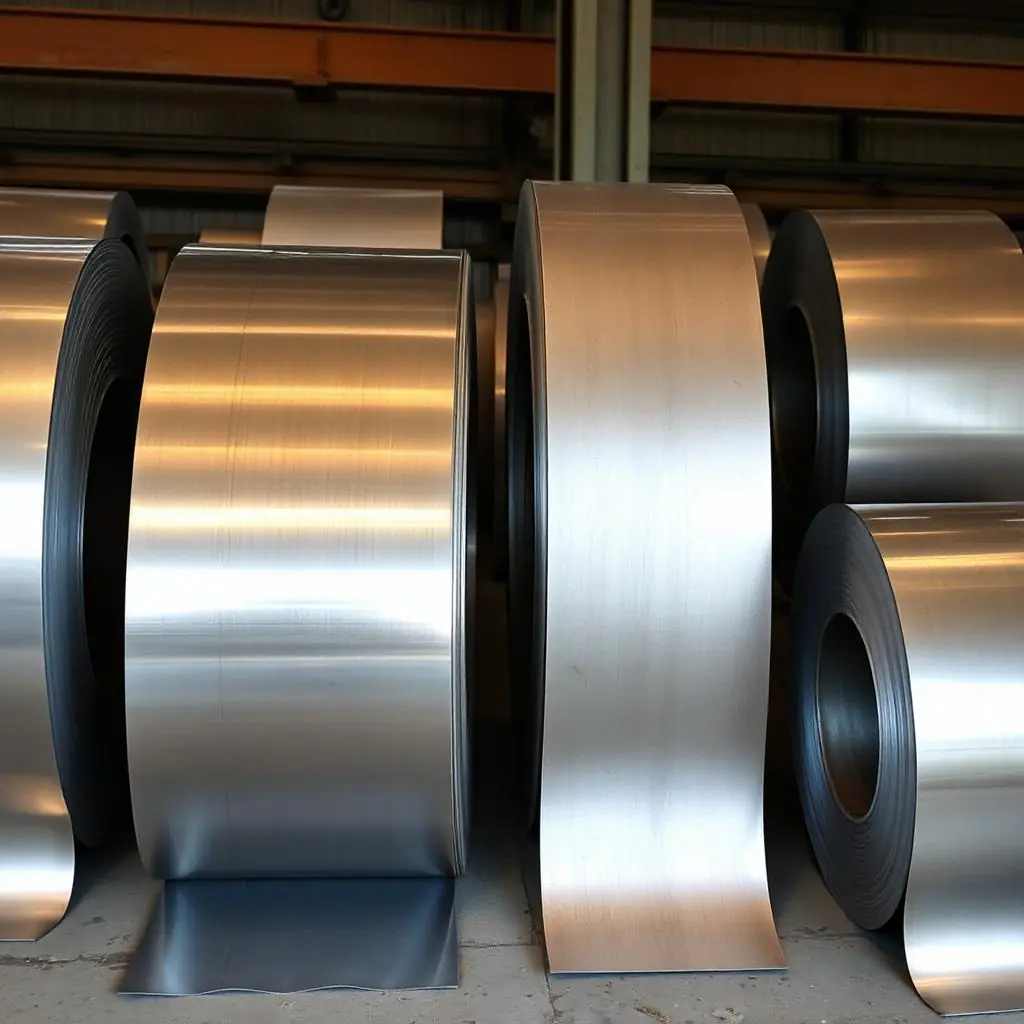

303 Stainless Steel Coil – The World’s Most Machinable Stainless Steel

When your CNC or automatic screw machine needs to run faster, 303 Stainless Steel Coil is the answer. With 0.15–0.35 % sulfur deliberately added, 303 delivers 2–3× faster machining speeds than 304 while still providing good corrosion resistance for mild atmospheres and food zones. The coil format feeds high-volume lines without interruption, reducing scrap and tooling costs. Whether you mass-produce precision screws, valve bodies, or instrument fittings, 303 Stainless Steel Coil maximises spindle uptime and profitability.

303 Stainless Steel Coil – Ultra-Machinable 2B Finish, Perfect for High-Volume CNC Production

Key Features & Benefits

- Free-machining sulfur 0.15–0.35 % – 2–3× faster production, longer tool life

- Excellent surface finish after turning, milling, or light polishing

- Non-galling / non-seizing – ideal for moving screw-machine parts

- Good corrosion resistance for indoor, mild chemical, and food-contact applications

- Non-magnetic in annealed condition; low permeability after cold work

- Available in thin gauges (0.3–6 mm) for light-duty cladding or precision stampings

- Full ASTM A895 / EN 1.4305 / AMS 5640 compliance

- 100 % recyclable, RoHS compliant

Technical Specifications

Table 1 – Chemical Composition (ASTM A895)

| Element | Min % | Max % |

|---|---|---|

| Cr | 17.0 | 19.0 |

| Ni | 8.0 | 10.0 |

| S | 0.15 | 0.35 |

| C | — | 0.15 |

| Mn | — | 2.00 |

| Si | — | 1.00 |

| P | — | 0.045 |

| Fe | Balance |

Table 2 – Mechanical & Physical Properties vs 304

| Property | 303 Coil | 304 Coil |

|---|---|---|

| Tensile Strength | 620 MPa (90 ksi) min. | 515 MPa (75 ksi) |

| Yield Strength (0.2 %) | 310 MPa (45 ksi) min. | 205 MPa (30 ksi) |

| Elongation in 2" | 35 % min. | 40 % |

| Hardness HRB | 90–100 | 92 max. |

| Density | 8.0 g/cm³ (0.289 lb/in³) | 8.0 g/cm³ |

| Machinability Rating | 90 % (excellent) | 45 % (good) |

| Magnetic Permeability | <1.02 (annealed) | <1.02 |

Standard Sizes & Finishes

| Thickness (mm) | Width (mm) | Coil ID (mm) | Finish Options |

|---|---|---|---|

| 0.30 – 0.50 | 1000 / 1219 / 1250 | 508 | 2B, BA |

| 0.60 – 1.00 | 1000 / 1219 / 1250 / 1500 | 508 | 2B, BA, No.4 |

| 1.20 – 3.00 | 1000 / 1219 / 1250 / 1500 | 508 / 610 | 2B, No.4, HL |

| 4.00 – 6.00 | 1219 / 1500 | 610 | No.1, HRAP |

| 8.00 – 12.0 | 1500 / 1524 | 610 | No.1, Pickled |

Custom slit widths from 20 mm; coil weight 2–25 tons.

Main Applications

- Automatic screw-machine parts: nuts, bolts, studs, washers

- Precision gears, shafts, bushings, couplings

- Valve and pump trim, pneumatic cylinders

- Instrument housings, sensor brackets, electronic connectors

- Aircraft fittings, seat-belt anchors, galley hardware

- Food-processing guides and rails (mild chloride environments)

- Decorative trim, elevator sills, architectural panels

2–3× Faster Machining – 303 Coil Enables Maximum Productivity on Automatic Screw Machines

Why Choose Our 303 Stainless Steel Coil

- ISO 9001 & PED certified mill – EN 10204 3.1/3.2 MTC supplied with every coil

- 100 000 ton annual capacity – 3–5 day lead time for standard sizes

- Precision slitting 6–1500 mm width, burr ≤0.03 mm, camber ≤1 mm/2 m

- Same-day shipment from 35 000 t stock – real-time coil portal

- Global export experience to 72 countries – fumigation-free crates, VCI film

- Factory-direct pricing – live surcharge update, fixed for 48 h after quotation

Massive Stock of 303 Stainless Steel Coil – Mill-Direct Supply, Same-Day Cutting & Delivery

Grade Comparison Table: 303 vs 304 vs 316 vs 303Se vs 416 vs 430F

| Grade | S Content | Mo % | Machinability Rating | Weldability | Magnetic | Relative Cost | Best Use |

|---|---|---|---|---|---|---|---|

| 303 | 0.15–0.35 | 0 | 90 % (excellent) | Poor | No* | 1.0× (base) | High-speed machining |

| 304 | ≤0.030 | 0 | 45 % (good) | Excellent | No* | 0.95× | General corrosion |

| 316 | ≤0.030 | 2–3 | 45 % (good) | Excellent | No* | 1.35× | Marine/chloride |

| 303Se | Se≥0.15 | 0 | 95 % (excellent) | Poor | No* | 1.1× | Ultra-smooth surface |

| 416 | ≥0.15 | 0 | 95 % (excellent) | Poor | Yes | 0.9× | Magnetic fasteners |

| 430F | ≥0.15 | 0 | 90 % (excellent) | Poor | Yes | 0.8× | Non-corrosive shafts |

*Non-magnetic in annealed condition; slight magnetism possible after cold work.

FAQ – 303 Stainless Steel Coil

-

What is the machinability rating of 303?

90 % (excellent) vs 45 % for 304 – chip break-up is superior, tool life 2–3× longer. -

Can 303 coil be welded?

Welding is not recommended due to hot-cracking risk; use 304 or 347 for welded joints and bolt on 303 parts. -

How does corrosion resistance compare with 304?

Slightly lower because of sulfur; adequate for indoor, food, and mild atmospheric service. -

What thickness tolerance do you guarantee?

ASTM A480/A895 standard; half-tolerance possible on request (±0.02 mm). -

How do I check current coil stock availability?

Login to our portal – live tonnage, coil ID, location, and certificate number updated every 30 minutes. -

What is the minimum order quantity?

One slit coil (≥500 kg) for stock items; master coils from 3 tons for mill direct. -

How often does the price change?

Linked to LME nickel and sulfur additive index – updated daily at 08:00 CST; fixed for 48 h after quotation. -

Which surface finishes are in stock?

2B, BA, No.4, HL, and micro-peeled; custom polishing up to Ra 0.1 µm available.

Call-to-Action

Stop paying trader margins. Contact the world’s largest 303 Stainless Steel Coil stockist today for the most competitive price, immediate access to real-time coil stock, and same-day precision slitting.