409 Stainless Steel Coil – Premium Exhaust Grade Stainless Steel for Automotive & High-Temperature Applications

Meta Description: Discover 409 stainless steel coil, ideal for automotive exhaust systems, with Ti/Nb stabilization, superior heat resistance, and cost savings vs 304. High-performance and affordable.

Introduction

409 Stainless Steel Coil is a ferritic stainless steel grade designed specifically for high-temperature and exhaust applications. It is a cost-effective alternative to austenitic grades like 304, offering excellent heat resistance, oxidation resistance, and durability at a significantly lower price point—up to 60-70% cheaper. This makes it the preferred material for automotive exhaust systems, including mufflers, catalytic converter shells, resonators, and flex pipes, as well as heat exchangers and furnace components.

The unique composition of 409 stainless steel provides high thermal fatigue resistance, outstanding weldability, and superior performance in harsh, high-temperature environments. Whether you're manufacturing parts for the automotive industry or designing industrial heat exchangers, 409 stainless steel coil delivers exceptional cost-performance benefits without compromising on quality.

The coil form is perfect for further processing into parts requiring intricate shapes or precise measurements, and with its excellent formability, it is widely used across industries where both structural integrity and aesthetic appeal are required. With Ti-stabilized and Nb-stabilized variants, 409 stainless steel coil provides added stability against sensitization, making it ideal for long-term thermal cycling.

This product detail page covers the key features, technical specifications, advantages, and applications of 409 stainless steel coil. Read on to discover why 409 stainless steel coil is the ultimate choice for exhaust systems and high-temperature applications.

Product Overview & Unmatched Advantages

- Massive Cost Savings: 409 stainless steel coil is significantly more affordable than 304 stainless steel, making it the best choice for cost-sensitive projects, especially in the automotive exhaust industry.

- Heat-Resistant: With excellent resistance to high temperatures (up to 850°C), 409 stainless steel coil performs well in exhaust systems, mufflers, and other high-heat applications.

- Ferritic Structure: The ferritic nature of 409 stainless steel allows it to maintain its strength and corrosion resistance at elevated temperatures, with added benefits of being fully magnetic.

- Weldability & Formability: The material offers excellent weldability and formability, making it easy to process into complex shapes and assemblies commonly required in exhaust systems.

- Stabilized Grades: 409 stainless steel coil is available in both Ti-stabilized and Nb-stabilized grades, ensuring enhanced resistance to sensitization and superior performance in long-term thermal cycling.

- Outstanding Oxidation Resistance: This material offers superior oxidation resistance, with the ability to withstand continuous service temperatures between 750-850°C, making it the ideal choice for automotive exhausts.

- Versatility: Available in various finishes, including 2B, No.1 hot-rolled, and polished, 409 stainless steel coil is suitable for a wide range of applications beyond automotive exhaust systems, such as heat exchangers and agricultural equipment.

409 stainless steel coil is the material of choice for a variety of industrial applications requiring heat and corrosion resistance, excellent mechanical properties, and low-cost solutions. Its ability to achieve a high level of formability and weldability ensures its dominance in both the OEM and aftermarket automotive exhaust markets.

Chemical Composition

| Element | Ti-Stabilized 409 (%) | Nb-Stabilized 409 (%) |

|---|---|---|

| Carbon (C) | ≤0.08 | ≤0.08 |

| Manganese (Mn) | ≤1.00 | ≤1.00 |

| Silicon (Si) | ≤1.00 | ≤1.00 |

| Phosphorus (P) | ≤0.04 | ≤0.04 |

| Sulfur (S) | ≤0.03 | ≤0.03 |

| Chromium (Cr) | 10.50 – 11.50 | 10.50 – 11.50 |

| Nickel (Ni) | ≤0.50 | ≤0.50 |

| Titanium (Ti) | 0.5 – 1.0 | - |

| Niobium (Nb) | - | 0.03 – 0.05 |

The difference between the Ti-stabilized and Nb-stabilized grades lies in the alloying element used to prevent sensitization. Ti-stabilized grades are ideal for preventing intergranular corrosion, while Nb-stabilized grades provide enhanced stability for more demanding high-temperature applications.

Mechanical Properties

| Property | Annealed (Soft) | Elevated Temperature (750°C) |

|---|---|---|

| Yield Strength (MPa) | 275 – 350 | 200 – 250 |

| Ultimate Strength (MPa) | 450 – 550 | 350 – 450 |

| Elongation (%) | ≥25% | ≥10% |

| Hardness (HRB) | ≤90 | ≤95 |

The mechanical properties of 409 stainless steel coil ensure it can withstand both the initial stresses and long-term thermal cycling encountered in automotive exhaust systems and industrial applications. Its ability to maintain good strength and elongation even at elevated temperatures makes it an ideal choice for demanding environments.

Physical Properties

| Property | Value |

|---|---|

| Density (g/cm³) | 7.7 |

| Thermal Expansion (10⁻⁶/°C) | 11.3 |

| Thermal Conductivity (W/m·K) | 25.5 |

| Magnetic | Yes |

409 stainless steel coil’s low thermal expansion and high thermal conductivity make it suitable for high-heat applications, while its magnetic properties offer additional functional benefits for specific industrial uses.

409 vs 304 vs 430 vs 441 vs 439 Coil Comparison

| Property | 409 Stainless Steel | 304 Stainless Steel | 430 Stainless Steel | 441 Stainless Steel | 439 Stainless Steel |

|---|---|---|---|---|---|

| Cost | Low | High | Moderate | Moderate | Moderate |

| High-Temperature Oxidation | Good (750°C) | Excellent (900°C) | Moderate | Good | Good |

| Weldability | Excellent | Excellent | Good | Good | Good |

| Formability | Excellent | Excellent | Good | Good | Good |

| Magnetic | Yes | No | Yes | Yes | Yes |

409 stainless steel coil is a much more affordable alternative to 304, while offering comparable high-temperature oxidation resistance, particularly in automotive exhaust systems. Its magnetic properties and formability make it highly suitable for exhaust applications, where material performance at elevated temperatures is essential.

Standard Specifications

| Thickness (mm) | Width (mm) | ID (mm) | Finish Options |

|---|---|---|---|

| 0.3 – 6.0 | 20 – 1500 | 400/508/610 | 2B, 2D, No.1 Hot-Rolled, Polished, Brushed |

409 stainless steel coil is available in a wide range of thicknesses and widths, offering the flexibility required for different applications, including automotive exhausts and industrial components.

High-Temperature Performance & Stabilization Guide

- Ti-Stabilized 409 Coil: Titanium stabilization prevents sensitization and ensures superior performance in thermal cycling, ideal for exhaust systems exposed to intermittent heat fluctuations.

- Nb-Stabilized 409 Coil: Niobium stabilization improves high-temperature creep resistance, making it a better choice for parts exposed to prolonged high-temperature stress, such as heat exchangers.

Both variants of 409 stainless steel coil can perform reliably in temperatures up to 850°C, making them ideal for exhaust components like mufflers, resonators, and catalytic converter shells.

Major Applications

- Automotive Exhaust Systems: Mufflers, resonators, flex pipes, catalytic converter shells.

- Heat Exchangers: Components for heat transfer systems in various industries.

- Thermal Containers: Used in manufacturing of thermal shields and heat-resistant containers.

- Agricultural Equipment: Spreaders, fuel tanks, and other high-temperature parts.

- Railway Wagons: Components exposed to high heat and wear.

- Sugar Industry Tubes: Tubing used in sugar production that requires high-temperature durability.

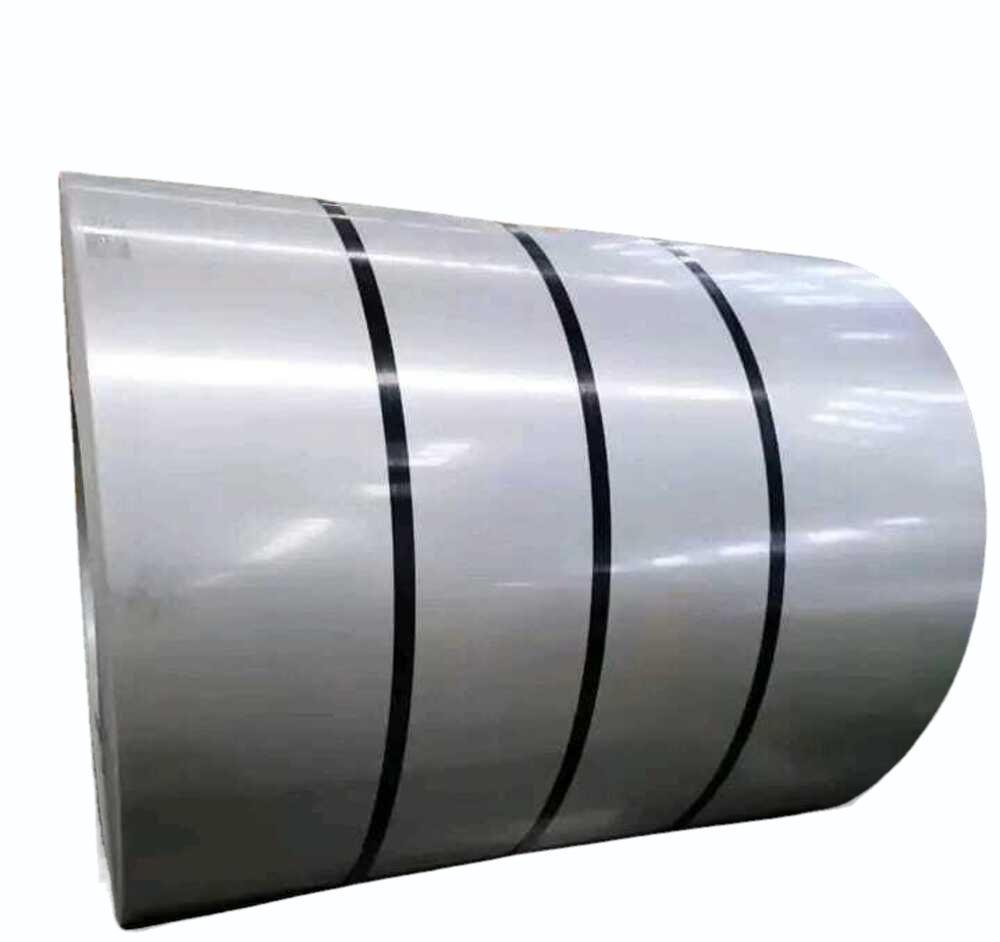

Caption: Large 409 stainless steel coils in 2B and polished finish stacked in warehouse

Caption: Large 409 stainless steel coils in 2B and polished finish stacked in warehouse Caption: Professional infographic 409 stainless steel coil data sheet + oxidation resistance chart up to 900 °C

Caption: Professional infographic 409 stainless steel coil data sheet + oxidation resistance chart up to 900 °C Caption: Real-world collage – 409 coil formed into exhaust pipes, muffler bodies, catalytic converter shells, and heat shields

Caption: Real-world collage – 409 coil formed into exhaust pipes, muffler bodies, catalytic converter shells, and heat shieldsWhy We Are the Best 409 Stainless Steel Coil Distributor

We are the No.1 409 stainless steel coil supplier globally, offering:

- 50,000+ tons permanent stock, ensuring consistent availability.

- Direct mill sourcing for both Ti and Nb-stabilized grades.

- Precision slitting with a tolerance of ±0.03 mm.

- Bright annealing available for superior finish.

available for superior finish.

- Full traceability with EN 10204 3.1/3.2 and AD2000 certificates.

- Fastest delivery worldwide, ensuring your production schedules stay on track.

- Unbeatable prices, ensuring maximum cost savings for our customers.

Packaging & Quality Standards

We take great care in packaging our products for export, ensuring safe transit with:

- VCI film for corrosion protection.

- Wooden pallets for stable support.

- Edge guards to prevent coil damage during transport.

FAQ Section

1. Is 409 stainless steel coil magnetic? Yes, 409 stainless steel is fully magnetic.

2. What is the maximum service temperature for 409? The maximum service temperature for 409 is around 850°C, making it suitable for high-temperature exhaust applications.

3. What is the difference between Ti-stabilized and Nb-stabilized 409? Ti-stabilized offers better resistance to sensitization, while Nb-stabilized provides enhanced high-temperature creep resistance.

4. Can 409 coil be welded easily? Yes, 409 stainless steel coil has excellent weldability, making it ideal for exhaust systems and other welded components.

5. Why use 409 instead of 304 for exhaust systems? 409 offers up to 60-70% cost savings over 304 while maintaining excellent high-temperature performance and oxidation resistance.

6. Does 409 rust? 409 is resistant to rust but can corrode in highly aggressive environments, so it’s recommended for use in less severe conditions.

7. What is the minimum order quantity? Our minimum order quantity depends on your project specifications, but we offer flexible quantities to suit your needs.

8. What is the lead time for polished 409 coil? Lead times for polished 409 stainless steel coil are typically 7-14 days, depending on order volume and customization.

9. Is 409 coil suitable for food-contact applications? 409 is often used in non-food-contact applications, though it may be suitable for specific food-grade environments based on local regulations.

Conclusion + Urgent Call-to-Action

Get your 409 stainless steel coil quote now and enjoy the fastest delivery, best prices, and highest quality. Contact us today through live chat, WhatsApp, WeChat, email, or phone. Our team is ready to assist you within 1 hour!

*Request your quote today and secure your supply of 409 stainless steel coil!