410 Stainless Steel Coil – High-Strength Martensitic Coil for Precision Applications

Meta Description: Discover high-quality 410 stainless steel coils for precision stamping, springs, and fasteners. Available in various finishes, with superior hardness and heat treatment options.

Introduction

410 Stainless Steel Coil is one of the most versatile martensitic stainless steel grades available in coil form. It is widely used in applications requiring a combination of high strength, corrosion resistance, and cost-effectiveness. The coil form offers greater flexibility for manufacturers in precision industries, including spring production, fastener manufacturing, medical device fabrication, and automotive trim production. Its unique martensitic structure allows for high hardness after heat treatment, making it ideal for components subject to wear and stress, such as blades, fasteners, and surgical instruments.

The coil form of 410 stainless steel offers significant advantages over traditional flat stock, including ease of processing, reduced waste, and improved efficiency in large-scale production runs. Moreover, 410 stainless steel can be easily heat-treated to achieve specific mechanical properties, allowing manufacturers to fine-tune material performance based on their needs.

In addition to its heat treatability, 410 stainless steel coil also offers excellent magnetic properties, which is important in various applications like actuators and sensors. Furthermore, its corrosion resistance is higher than many carbon steels, providing longer-lasting performance in harsh environments.

This product detail page will cover the chemical composition, mechanical properties, heat treatment options, applications, and the reasons why 410 stainless steel coil is the best choice for your manufacturing needs.

Product Overview & Key Benefits

- Martensitic Structure: Offers high strength and hardness, particularly when heat-treated. This makes it perfect for components like blades, springs, and fasteners.

- Corrosion Resistance: Provides excellent resistance to corrosion in various environments, including mildly acidic conditions and atmospheric exposure.

- Heat Treatable: Can be annealed, hardened, or tempered, allowing for fine-tuning of material properties based on specific needs.

- Magnetic Properties: Fully magnetic, making it suitable for applications in magnetic fields.

- Cost-Effective: More affordable than austenitic stainless steels, offering high performance at a lower cost.

- Versatile Coil Form: Can be slitted or wound into custom gauges and widths for use in precision stamping, spring manufacturing, and more.

- Wide Range of Finishes: Available in a variety of finishes, including 2B, 2D, BA, and No.4, suitable for different applications.

410 stainless steel coil is perfect for a wide range of industrial applications. Its ability to undergo precise heat treatments means that manufacturers can achieve specific hardness levels, making it ideal for products like surgical instruments, stamping parts, and pump components. Additionally, its magnetic properties make it suitable for a variety of technical and industrial applications where magnetic interaction is necessary.

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.15 – 0.40 |

| Manganese (Mn) | 1.0 – 1.50 |

| Silicon (Si) | ≤1.00 |

| Phosphorus (P) | ≤0.04 |

| Sulfur (S) | ≤0.03 |

| Chromium (Cr) | 11.50 – 13.50 |

| Nickel (Ni) | ≤0.75 |

| Molybdenum (Mo) | ≤0.25 |

| Nitrogen (N) | ≤0.10 |

Note: The specific composition may vary slightly based on the supplier or processing method, ensuring optimized mechanical properties for each application.

Mechanical Properties

| Property | Annealed (Soft) | Full-Hard (HRC 45-50) | Quenched & Tempered (HRC 35-55) |

|---|---|---|---|

| Yield Strength (MPa) | 310 – 450 | 550 – 750 | 650 – 950 |

| Ultimate Strength (MPa) | 550 – 750 | 800 – 1000 | 800 – 1100 |

| Elongation (%) | ≥35% | ≤5% | ≤10% |

| Hardness (HRC) | ≤25 | 45 – 50 | 35 – 55 |

| Impact Toughness (J) | 20 – 40 | 5 – 10 | 20 – 50 |

410 stainless steel coil is available in several hardness grades depending on the desired application. The annealed state offers excellent formability for manufacturing processes, while the hardened and tempered version provides superior strength for high-stress components.

Available Specifications

| Thickness (mm) | Width (mm) | ID (mm) | Finish Options |

|---|---|---|---|

| 0.1 – 6.0 | 5 – 1250 | 300/400/508 | 2B, 2D, BA, No.4, Polished |

The coil form allows for easy handling, with thicknesses ranging from 0.1 mm to 6.0 mm and widths up to 1250 mm. The ID of the coils is available in standard sizes such as 300 mm, 400 mm, and 508 mm, making it adaptable to various manufacturing needs. With different finishes, such as 2B, 2D, BA, and No.4, 410 stainless steel coil is versatile enough to suit diverse applications, from industrial stamping to consumer product fabrication.

410 vs 410S vs 420 vs 301 vs 304 Coil Comparison

| Property | 410 Stainless Steel | 410S Stainless Steel | 420 Stainless Steel | 301 Stainless Steel | 304 Stainless Steel |

|---|---|---|---|---|---|

| Hardness Potential | 45–55 HRC | 35–45 HRC | 50–55 HRC | 30–35 HRC | 40–50 HRC |

| Weldability | Poor | Good | Poor | Good | Excellent |

| Cost | Low | Moderate | Moderate | Moderate | High |

| Applications | Blades, Springs | Fasteners, Kitchen Utensils | Surgical Instruments | Springs, Washers | Food Processing, Kitchen Utensils |

| Corrosion Resistance | Moderate | Good | Moderate | Good | Excellent |

410 stainless steel coil offers excellent hardness and strength compared to other martensitic stainless steels. It is more cost-effective than 420 or 304 grades while still providing good corrosion resistance for most applications.

Heat Treatment Options for 410 Stainless Steel Coil

410 stainless steel coil can be treated in various ways to enhance its mechanical properties. Heat treatment options include:

- Annealing: Heating to 800–900°C, followed by slow cooling. This process softens the material, improving formability and reducing hardness.

- Hardening: Heating to 950–1050°C, followed by rapid cooling. This increases hardness and strength.

- Tempering: Heating the quenched material to 400–600°C to achieve the desired hardness. For example, spring materials are tempered at temperatures around 500°C to balance strength and ductility.

410 stainless steel coil responds well to heat treatment, enabling manufacturers to tailor the material’s mechanical properties to specific requirements.

Major Applications

- Springs: Due to its excellent hardness and strength after heat treatment, 410 stainless steel coil is ideal for producing durable springs.

- Fasteners: Used in high-stress environments where corrosion resistance and strength are needed.

- Blades: Common in cutting tools, knives, and other blade-type products due to its sharpness and durability.

- Surgical Instruments: Ideal for medical applications, including scalpels and tweezers, because of its hardness and edge retention.

- Valve Parts and Pump Components: Used in high-pressure, high-wear applications where corrosion resistance and strength are essential.

- Stamping Parts: Perfect for precision stamping applications, offering durability and fine finish.

- Automotive Trim: Utilized for parts requiring resistance to wear and corrosion, like automotive trim.

- Kitchen Utensils: Such as knives and forks, due to its corrosion resistance and aesthetic finishes.

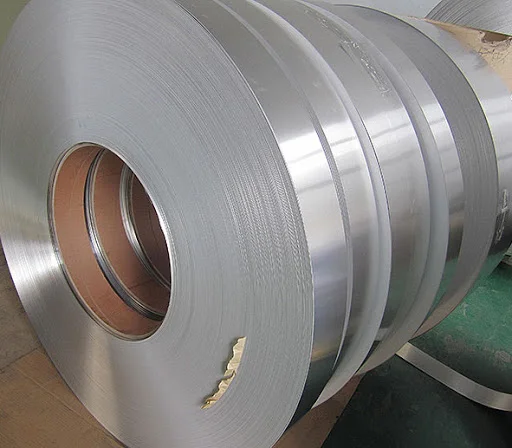

Caption: Multiple 410 stainless steel coils stacked in warehouse (2B and polished finish, clearly showing mill edge/slit edge)

Caption: Multiple 410 stainless steel coils stacked in warehouse (2B and polished finish, clearly showing mill edge/slit edge) Caption: Professional infographic 410 stainless steel coil data sheet + hardness vs tempering temperature curve

Caption: Professional infographic 410 stainless steel coil data sheet + hardness vs tempering temperature curve Caption: Application collage – 410 coil processed into doctor blades, spring components, hardened stamping parts, and surgical scalpels

Caption: Application collage – 410 coil processed into doctor blades, spring components, hardened stamping parts, and surgical scalpelsWhy We Are the Best 410 Stainless Steel Coil Distributor

We are the leading 410 stainless steel coil supplier, offering:

- Massive Stock: Over 3000 tons of 410 stainless steel coils available for immediate shipment.

- Precision Slitting: Slitting tolerances of ±0.03 mm for high-precision requirements.

- Custom Annealing & Hardening: Tailored heat treatment services for specific applications.

- Oscillated Winding Available: Custom coil winding for easier processing.

- Full Traceability: EN 10204 3.1/3.2 certificates provided with every order.

- Fastest Delivery: Quick turnaround times for international shipping.

- Most Competitive Price: Offering the best value worldwide on 410 stainless steel coil.

Packaging & Delivery Standards

- Export Seaworthy Packing: Secure, durable packaging for safe transportation.

- Wooden Pallets & Steel Strip Reinforcement: Ensures coils are securely packed.

- Protective Film Options: Available to prevent surface damage during transit.

FAQ Section

1. Can 410 stainless steel coil be hardened after slitting? Yes, 410 stainless steel coil can be hardened after slitting through heat treatment processes.

2. What is the difference between 410 and 410S coil? 410S has a lower carbon content, making it less hardenable but more corrosion-resistant compared to 410.

3. What is the maximum hardness achievable with 410 coil? The maximum hardness achievable for 410 coil is around 55 HRC after proper heat treatment.

4. Is 410 stainless steel coil magnetic? Yes, 410 stainless steel is fully magnetic due to its martensitic structure.

5. What is the best tempering temperature for springs? For springs, tempering is typically done at 500°C to achieve the desired hardness and flexibility.

6. Can 410 stainless steel coil be polished to a mirror finish? Yes, 410 stainless steel can be polished to a high-gloss finish, particularly in its softer, annealed state.

7. What is the minimum order quantity? The minimum order quantity depends on the specific requirements, but typically, coils are available in full coil quantities.

Conclusion + Strong Call-to-Action

For the best 410 stainless steel coil, request an instant quote today! Get in touch with us via live chat, WhatsApp, email, or phone, and receive a fast, 24-hour response. We are your No.1 410 stainless steel coil distributor worldwide.

Request Your Quote Now and Start Your Order!