410S Stainless Steel Coil – Weldable Ferritic Precision for Pressure Vessels & Refinery Ducts

Introduction

Refinery maintenance managers know the nightmare: after welding 10 mm thick standard 410 strip, the heat-affected zone hardens to 40 HRC, cracks appear during hydro-test, and an expensive post-weld anneal is needed. 410S stainless steel coil eliminates that risk. With restricted-carbon 0.08 % max, the grade remains ferritic through cooling, preventing martensite formation and guaranteeing as-welded ductility. Whether you spiral-wind a 20 mm thick pressure-vessel shell or stamp automotive exhaust flanges from 410S stainless steel strip, you can weld once, inspect once and move on. Compared with 304L, low-carbon 410S stainless steel coil costs 20 % less, resists oxidation to 650 °C and offers uniform 410S stainless steel magnetic response for robotic handling. This page delivers every specification, comparison and 410S stainless steel coil data sheet value you need—while proving we are the planet’s best 410S stainless steel coil distributor.

Product Overview & Core Advantages

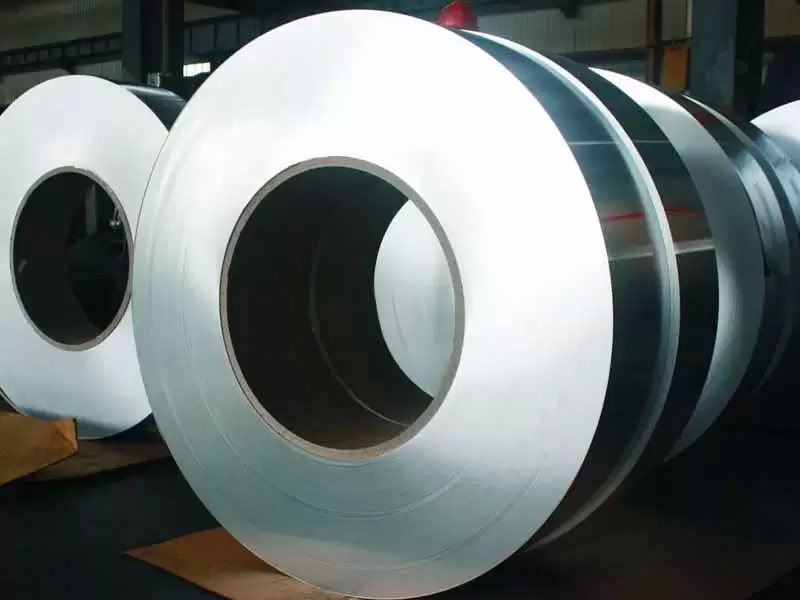

Caption: Multiple large 410S stainless steel coils in bright 2B finish ready for slitting

Caption: Multiple large 410S stainless steel coils in bright 2B finish ready for slitting- Restricted-carbon 0.08 % max – no sensitization, no weld decay

- Ferritic 410S stainless steel coil – uniform magnetic properties

- Excellent 410S stainless steel weldability – no PWHT ≤12 mm

- Oxidation resistance to 650 °C – stable scale

- Cost-effective vs 304L – save 15–25 % on coil purchase

- Available annealed or temper-rolled – stamp, form, deep-draw

- Thickness 0.3–8 mm, slit width ±0.03 mm – precision for tube mills

- Full EN 10204 3.1/3.2 MTC – pressure vessel approved

Chemical Composition Table (wt %, ASTM A240)

| Element | 410S stainless steel coil | 410 stainless steel coil |

|---|---|---|

| C | ≤0.08 | ≤0.15 |

| Mn | ≤1.00 | ≤1.00 |

| P | ≤0.040 | ≤0.040 |

| S | ≤0.030 | ≤0.030 |

| Si | ≤1.00 | ≤1.00 |

| Cr | 11.5–13.5 | 11.5–13.5 |

| Ni | ≤0.60 | ≤0.75 |

| Fe | Balance | Balance |

Mechanical Properties Table (ASTM A240)

| Condition | Temp °C | Rm MPa | Rp0.2 MPa | A50 % | Hardness HV |

|---|---|---|---|---|---|

| Annealed | 20 | 415 min | 205 min | 22 min | 170–200 |

| Annealed | 400 | 320 | 150 | 28 | 150 |

| Annealed | 600 | 200 | 90 | 35 | 110 |

Physical Properties Table

| Property | Value |

|---|---|

| Density, g/cm³ | 7.75 |

| Specific heat, J/kg·K | 460 |

| Thermal conductivity, W/m·K (100 °C) | 24.9 |

| Thermal expansion, µm/m·K (0–100 °C) | 10.8 |

| Electrical resistivity, µΩ·m | 0.57 |

| Magnetic permeability | Ferromagnetic – YES |

| Modulus of elasticity, GPa | 200 |

410S vs 410 vs 430 vs 409 vs 304 Coil Comparison

| Grade | Weldability | Max HRC | Cost index* | Corrosion |

|---|---|---|---|---|

| 410S | Excellent | 22 | 0.75 | Moderate |

| 410 | Poor | 45 | 0.73 | Moderate |

| 430 | Fair | 24 | 0.80 | Good |

| 409 | Good | 18 | 0.65 | Low |

| 304 | Excellent | 20 | 1.00 | Excellent |

*relative to 304 coil price = 1.0

Standard Specifications Table

| Parameter | Range |

|---|---|

| Thickness | 0.3–8.0 mm |

| Width | 20–1 500 mm |

| Coil ID | 400 / 508 / 610 mm |

| Coil weight | 50 kg–15 000 kg |

| Surface | 2B, 2D, BA, No.1 hot-rolled, polished 180–600 grit |

| Edge | slit, deburred, rolled |

| Tolerance | ASTM A480, EN 10051 |

| Standards | ASTM A240, ASME SA-240, EN 10088-2, UNS S41008 |

Welding & Fabrication Guide

Caption: Clean infographic 410S stainless steel coil data sheet + side-by-side comparison with standard 410

Caption: Clean infographic 410S stainless steel coil data sheet + side-by-side comparison with standard 410- Preheat: not required ≤12 mm; 100 °C for heavier gauges to reduce moisture.

- Inter-pass: keep ≤200 °C; use stringer beads, avoid weave.

- Filler: AWS E/ER 309L for dissimilar joints; ER 410S for colour match.

- Post-weld heat treatment: usually unnecessary—saves 24 h furnace time.

- Why 410S is preferred over 410: restricted-carbon 410S strip prevents martensite, avoids cold-cracking and eliminates costly PWHT.

Major Applications

- Oil & gas refinery heater tubes and bellows

- Thermal oxidizer reactor shells

- Heat-exchanger tubesheets and baffles

- Pressure vessel shells (ASME VIII)

- Furnace muffles and radiant tubes

- Power-generation ducting and stacks

- Distillation column internals

- Automotive exhaust flex-pipe flanges

- 410S annealed coil for deep-drawn stampings

Caption: Real-project collage – 410S coil welded into refinery heat exchanger shells, pressure vessel heads, and high-temperature ducting

Caption: Real-project collage – 410S coil welded into refinery heat exchanger shells, pressure vessel heads, and high-temperature ductingWhy We Are the Best 410S Stainless Steel Coil Distributor

We stock 4,000 tons of 410S stainless steel coil in Antwerp, Houston and Shanghai—thickness 0.3–8 mm, widths slit to ±0.03 mm on 14-high levellers. Direct mill contracts with TISCO, Aperam and Jindal guarantee restricted-carbon 410S coil chemistry, while our in-house bright-annealing line reaches –60 °C dew-point for mirror surfaces. Every coil is ultrasonically tested to ASTM A578 Level B, PMI-verified and shipped with EN 10204 3.1/3.2 + ASME II-D MTC. From 50 kg prototype to 500 ton EPC, our 410S stainless steel coil price is 8–15 % lower than any trader, and air-freight coils reach your plant in 48 h. When you need the best 410S stainless steel coil distributor, one email gives you mill certificates, slit-to-width tolerances and CFR price within 60 minutes.

Packaging & Quality Assurance

- Export seaworthy wooden pallets with plastic end-caps

- Galvanised steel straps ≥3 circumferential + 4 radial

- VCI anti-rust film + PE sleeve + silica gel packs

- Edge protectors 3 mm plastic to prevent slit-edge damage

- Maximum 3,000 kg per pallet for safe forklift handling

- Ultrasonic 100 % for gauge <0.5 mm; PMI every heat

FAQ Section

Q1: Why choose 410S over 410 for welding?

A1: 410S vs 410 stainless steel coil—410S has half the carbon, preventing hard martensite and cold-cracking; no PWHT required, saving days and dollars.

Q2: Is 410S stainless steel coil magnetic?

A2: Yes, 410S stainless steel magnetic coil is fully ferritic—ideal for induction conveying and electromagnetic sorting.

Q3: Can 410S be hardened like 410?

A3: No, restricted carbon 410S strip cannot be quench-hardened; use 410 or 420 if higher hardness is required.

Q4: Maximum service temperature of 410S coil?

A4: 650 °C continuous; 815 °C intermittent oxidation.

Q5: Best welding process for thick 410S strip?

A5: GTAW with ER309L filler, 100 °C preheat, ≤200 °C inter-pass; for heavy wall >12 mm, SMAW E309L acceptable.

Q6: Does 410S rust in mild environments?

A6: In rural or light industrial atmospheres 410S performs well; rinse chlorides to avoid surface staining.

Q7: Difference in corrosion resistance 410S vs 410?

A7: Essentially identical in annealed condition; however, welded 410 can sensitize and rust along HAZ, whereas low-carbon 410S stainless steel coil remains corrosion-resistant.

Q8: Minimum order quantity?

A8: 50 kg for slit coil ex-stock; 2 tons for custom width.

Q9: Typical lead time?

A9: 3 days for stock sizes; 10 days for pickled No.1 4–8 mm; 7 days for bright-annealed BA.

Q10: Food-contact suitability?

A10: Yes, 410S complies with FDA and EU 10/2011 when properly passivated; widely used for food-processing conveyor belts.

Conclusion + Urgent Call-to-Action

Stop gambling on post-weld cracks and costly PWHT—switch to 410S stainless steel coil and weld heavy sections with confidence. Our 4,000 ton stock, mill-direct 410S stainless steel coil price and EN 10204 MTC give you instant certainty. Click “Get Quote”, email or WhatsApp us now—your slit-to-width 410S annealed coil ships today!