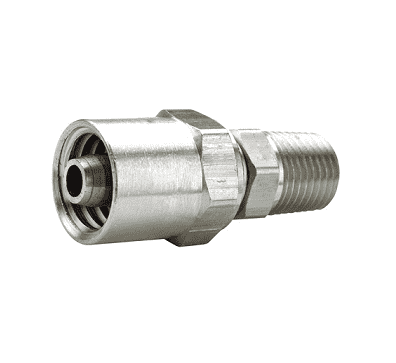

303 Stainless Steel Fittings – The World’s No.1 Free-Machining Grade for High-Volume CNC Production

When your automatic screw machine or CNC lathe needs to run faster, 303 Stainless Steel Fittings deliver the competitive edge. With 0.15–0.35 % sulfur deliberately added, this austenitic grade offers 2–3× higher machining speeds and superior chip-breaking compared to standard 304 or 316, while still providing good corrosion resistance for mild-service applications. From bright-bar hex nipples and hose barbs to precision-turned instrumentation elbows, 303 Stainless Steel Fittings maximise spindle uptime, extend tool life, and reduce unit cost—making them the first choice for high-volume producers of pneumatic, hydraulic, and food-processing components worldwide.

303 Stainless Steel Fittings – Ultra-Machinable Threaded & Turned Components for High-Volume Production

Key Features & Benefits

- Free-machining sulfur 0.15–0.35 % – 90 % machinability rating vs 45 % for 304

- Excellent chip break-up – longer tool life, lower production cost

- Good corrosion resistance for indoor, food-zone, and mild chemical environments

- Non-galling / non-seizing – ideal for moving screw-machine parts

- Non-magnetic in annealed condition; low permeability after cold work

- Available in both standard and precision-machined specials

- Full ASTM A582, ASME B16.11, EN 1.4305 compliance

- 100 % recyclable, RoHS compliant

Technical Specifications

Table 1 – Chemical Composition (ASTM A582)

| Element | 303 % | 303Se % | 304 % |

|---|---|---|---|

| Cr | 17.0–19.0 | 17.0–19.0 | 18.0–20.0 |

| Ni | 8.0–10.0 | 8.0–10.0 | 8.0–10.5 |

| S | 0.15–0.35 | ≤0.060 | ≤0.030 |

| Se | — | ≥0.15 | — |

| C | ≤0.15 | ≤0.15 | ≤0.08 |

| Fe | Balance | Balance | Balance |

Table 2 – Mechanical & Machinability Data

| Property | 303 Fittings | 304 Fittings | 316 Fittings |

|---|---|---|---|

| Tensile Strength | ≥620 MPa | ≥515 MPa | ≥515 MPa |

| Yield Strength (0.2 %) | ≥310 MPa | ≥205 MPa | ≥205 MPa |

| Elongation in 2" | ≥35 % | ≥40 % | ≥40 % |

| Hardness HRB | 90–100 | ≤92 | ≤95 |

| Machinability Rating | 90 % (excellent) | 45 % (good) | 45 % (good) |

| Chip Break-Up | Superior | Fair | Fair |

| Weldability | Poor* | Excellent | Excellent |

*Welding not recommended due to hot-cracking risk; use 304/347 for welded joints and bolt on 303 parts.

Full Product Range Table

| Fitting Type | Size Range | Pressure Class | Standards | Finish |

|---|---|---|---|---|

| 303 stainless steel fittings – threaded (NPT, BSPT, BSPP) | ⅛"–4" | 150 lb / 3000 lb / 6000 lb | ASME B16.11, ISO 7-1 | Pickled, bright |

| Socket-weld forged | ¼"–4" | 3000 lb / 6000 lb | ASME B16.11 | Pickled |

| Hose barbs & hose fittings | ⅛"–2" | 250 psi | Custom | Bright |

| Compression & instrumentation | ⅛"–2" | 10 000 psi | DIN 2353, ISO 8434-1 | Bright annealed |

| Turned hex nipples, bushings, plugs | ⅛"–2" | Custom | ASTM A582 | Bright |

| Elbows, tees, crosses, couplings | ⅛"–4" | Custom | ASTM A582 | Bright |

| Custom CNC machined specials | 5–200 mm | Custom | ASTM A314 | Mirror Ra ≤0.4 µm |

Special selenium-grade 303 stainless steel fittings available on request.

Main Applications

- Automatic lathe & CNC mass production of precision components

- Pneumatic & hydraulic systems – quick-connect nipples, adapters

- Instrumentation – compression fittings, sensor housings

- Valve parts, pump trim, compressor components

- Food-processing equipment parts requiring extensive machining

- Automotive fasteners, electronic connectors, terminal blocks

- 303 stainless steel fittings for low-pressure dairy lines

2–3× Faster Machining – 303 Stainless Steel Fittings Ideal for Automatic Screw Machines & CNC Shops

Why Choose Us – Machining-Grade Specialist

- ISO 9001 & PED certified mill – EN 10204 3.1 & 3.2 MTC supplied

- 150 000 tons annual machining-grade stainless capacity – 5-day lead time

- In-house threading & turning lines – NPT, BSPP, BSPT, metric, UNF

- Same-day shipping for standard 303 stainless steel fittings – 30 000 t ready stock

- Custom CNC specials within 7 days – tolerances ±0.05 mm

- Global export to 70+ countries – fumigation-free crates, vessel booking, insurance

Massive Ready Stock of 303 Stainless Steel Fittings – Mill-Direct Prices, Ships Today Worldwide

Grade Comparison Table: 303 vs 303Se vs 304 vs 316 vs 416 vs 430F Fittings

| Grade/Type | S/Se % | Mo % | Machinability | Weldability | Magnetic | Relative Cost | Best Use |

|---|---|---|---|---|---|---|---|

| 303 | S 0.15–0.35 | 0 | 90 % | Poor | No* | 1.0× (base) | High-speed machining |

| 303Se | Se ≥0.15 | 0 | 95 % | Poor | No* | 1.1× | Ultra-smooth finish |

| 304 | ≤0.030 | 0 | 45 % | Excellent | No* | 0.95× | General corrosion |

| 316 | ≤0.030 | 2–3 | 45 % | Excellent | No* | 1.35× | Marine chloride |

| 416 | S ≥0.15 | 0 | 95 % | Poor | Yes | 0.9× | Magnetic fasteners |

| 430F | S ≥0.15 | 0 | 90 % | Poor | Yes | 0.8× | Non-corrosive shafts |

*Non-magnetic in annealed condition; slight magnetism possible after cold work.

FAQ – 303 Stainless Steel Fittings

-

What is the machinability rating of 303 stainless steel fittings?

90 % (excellent) vs 45 % for 304; chip break-up is superior, tool life 2–3× longer. -

Can 303 stainless steel fittings be welded?

Welding is not recommended due to hot-cracking risk; use 304/347 for welded joints and bolt on 303 parts. -

Difference between 303 and 303Se fittings?

303Se contains ≥0.15 % selenium instead of sulfur, providing even better chip breaking and smoother surface finish. -

What is current stock status for 303 stainless steel fittings?

30 000 t ready stock; live portal updated every 30 minutes. -

What is the minimum order quantity?

One carton for stock items; full container (≈20 t) for custom CNC specials. -

Lead time for custom CNC parts?

7 days for specials; 24 h for standard 303 stainless steel fittings. -

Which certificates accompany the shipment?

EN 10204 3.1/3.2 MTC, ISO 9001, PED 2014/68/EU, and third-party inspection (SGS/TÜV/BV). -

Which countries receive your exports?

More than 70 countries including USA, Germany, India, Brazil, UAE, South Korea, and Australia.

Call-to-Action

Stop paying trader margins. Contact the largest 303 stainless steel fittings producer today for the most competitive price, immediate access to massive stock, and same-day shipping of any 303 stainless steel fittings.