503 Stainless Steel Fittings: High-Temperature Excellence for Demanding Applications

Meta Description: Discover 503 stainless steel fittings with exceptional heat resistance up to 980°C, oxidation resistance, and cost savings compared to 309/310 fittings. Available in buttweld, threaded, and socket weld types.

Introduction

503 stainless steel fittings are engineered to meet the toughest demands in high-temperature applications. With an impressive continuous service temperature of 980°C, these fittings are a perfect solution for environments subjected to extreme heat and oxidative conditions. Offering up to 50% cost savings when compared to austenitic alloys like 309 and 310, 503 stainless steel fittings provide outstanding performance while significantly reducing operational costs.

Designed with a ferritic structure, 503 stainless steel fittings exhibit excellent oxidation resistance, making them ideal for applications in furnace tubes, thermal oxidizers, and high-heat environments in industries such as petrochemical refining, cement production, and power generation. These fittings excel in their ability to resist scaling, sulfidation, and carburization at elevated temperatures, offering unmatched durability over extended periods of service.

By selecting 503 stainless steel fittings, you’re choosing a material that delivers the best value with high resistance to thermal expansion, reduced maintenance costs, and excellent weldability. As the leading supplier and distributor of 503 stainless steel fittings, we pride ourselves on providing top-quality products and competitive pricing for clients across the globe.

Product Overview & Extreme Advantages

- Exceptional Heat Resistance: 503 stainless steel fittings can withstand continuous service temperatures of up to 980°C, making them ideal for high-temperature applications in industries like furnace systems, thermal oxidizers, and refinery heater systems.

- Cost Savings: Compared to 309 and 310 stainless steel fittings, 503 fittings offer up to 50% lower cost, making them a more economical option without sacrificing quality.

- Ferritic Structure: The ferritic structure of 503 stainless steel ensures no phase changes at elevated temperatures, reducing the risk of embrittlement and ensuring long-term reliability in high-heat environments.

- Excellent Oxidation Resistance: With superior oxidation resistance, 503 stainless steel fittings maintain structural integrity in environments exposed to high-temperature air and other oxidizing agents.

- Superior Scaling Resistance: These fittings are scaling resistant, preventing the formation of harmful oxides on the surface, which improves durability and reduces maintenance costs.

- Weldability and Formability: The material’s stable ferritic structure makes 503 stainless steel fittings highly weldable, offering greater flexibility during fabrication and installation.

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Chromium (Cr) | 4.5–6.0 |

| Carbon (C) | ≤ 0.03 |

| Molybdenum (Mo) | 0.5–1.0 |

| Nickel (Ni) | ≤ 0.5 |

| Iron (Fe) | Balance |

| Niobium (Nb) | ≤ 0.1 |

The 503 stainless steel fittings are composed of 4.5–6.0% chromium, ensuring excellent resistance to oxidation. The low carbon content and typical molybdenum stabilization improve performance in high-temperature, corrosive environments.

Mechanical Properties

| Property | Value at Room Temperature | Value at 600 °C | Value at 800 °C | Value at 900 °C |

|---|---|---|---|---|

| Yield Strength (MPa) | 250 | 230 | 220 | 210 |

| Ultimate Tensile Strength (MPa) | 550 | 520 | 510 | 500 |

| Elongation (%) | 22 | 20 | 18 | 16 |

| Hardness (HRB) | 80 | 70 | 65 | 60 |

503 stainless steel fittings maintain outstanding mechanical properties even at high temperatures, offering excellent tensile strength, elongation, and hardness, making them perfect for high-pressure and high-temperature applications.

High-Temperature Oxidation & Scaling Resistance

| Property | Value |

|---|---|

| Maximum Continuous Service Temperature (°C) | 980 |

| Intermittent Service Temperature (°C) | 1000 |

| Oxidation Resistance (g/m²) | 0.35 (at 1000°C for 1000 hours) |

| Scaling Resistance | Excellent up to 980°C |

| Creep Resistance at 900°C | 220 MPa |

503 stainless steel fittings provide excellent oxidation and scaling resistance, maintaining structural integrity and surface quality in extreme temperatures, even under continuous exposure to oxidizing gases.

503 vs 502 vs 410 vs 430 vs 304 vs 309 Fittings Comparison

| Property | 503 Stainless Steel | 502 Stainless Steel | 410 Stainless Steel | 430 Stainless Steel | 304 Stainless Steel | 309 Stainless Steel |

|---|---|---|---|---|---|---|

| Max Service Temperature (°C) | 980 | 980 | 800 | 870 | 870 | 1150 |

| Oxidation Resistance | Excellent | Excellent | Fair | Good | Fair | Excellent |

| Cost | Low | Low | Medium | Medium | High | High |

| Weldability | Excellent | Excellent | Fair | Good | Excellent | Excellent |

| Formability | Excellent | Excellent | Good | Good | Excellent | Good |

When compared to 502, 410, 430, and 309, 503 stainless steel fittings are more cost-effective while offering superior oxidation resistance at higher temperatures, making them the best value for high-temperature applications.

Available Types & Specifications

| Type | Buttweld (seamless & welded), Threaded, Socket Weld |

|---|---|

| Size | 1/2″–48″ (buttweld); 1/8″–4″ (forged) |

| Pressure | Sch 10S–XXS; 2000#–9000# |

| Standards | ASTM A403 WP503, A182 F503, ASME B16.9, B16.11, MSS SP-43/75/79/83/95/97 |

| Surface | Pickled, Shot-blasted, Annealed & Pickled |

We offer 503 stainless steel fittings in a wide variety of configurations and sizes. Available as buttweld, threaded, and socket weld fittings, sizes range from 1/2″ to 48″ for buttweld fittings and 1/8″ to 4″ for forged fittings. These fittings are available in a range of pressure ratings and surface finishes to meet any industrial requirements.

High-Temperature Performance Guide

503 stainless steel fittings perform optimally in high-temperature environments with excellent resistance to sulfidation and carburization. Their low thermal expansion and scaling resistance make them suitable for use in furnace systems, thermal oxidizers, and other high-heat applications.

Major Applications

- Furnace fittings

- Kiln tube connections

- Radiant tube elbows

- Recuperator fittings

- Soot-blower piping

- Pyrolysis coil fittings

- Cement kiln inlet fittings

- Glass lehr rollers & connections

- Burner nozzle fittings

- Heat exchanger tube-to-tubesheet fittings

- Thermal oxidizer piping

- Refinery heater fittings

These 503 stainless steel fittings are used in industries where high-heat resistance and long-term reliability are essential, including cement plants, power generation, and petrochemical refining.

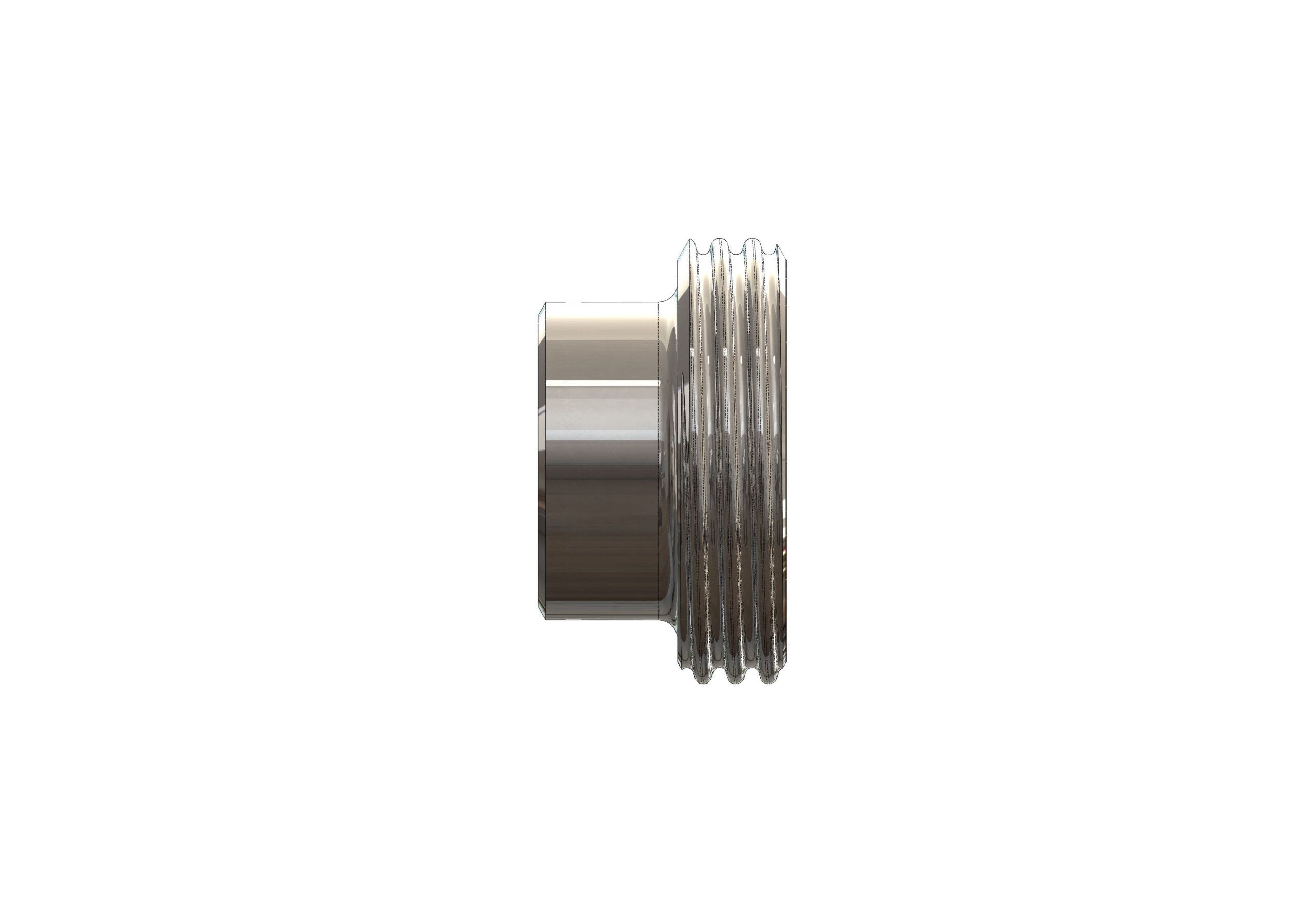

Product Images

Hot-rolled 503 stainless steel fittings ready for shipment

Professional infographic 503 stainless steel fittings data sheet + oxidation resistance curve up to 1100°C

Real-application collage – 503 fittings used in furnace tubes, recuperator tubes, pyrolysis coils, and high-temperature components

Why We Are the Best 503 Stainless Steel Fittings Distributor

As the global No.1 supplier of 503 stainless steel fittings, we offer:

- Largest stock of high-temp 503 fittings for immediate delivery

- Direct mill contracts, ensuring the best prices and availability

- In-house pickling & solution annealing for superior surface quality

- 100% ultrasonic & radiographic testing to ensure top quality

- Full EN 10204 3.1/3.2 + PED 2014/68/EU certifications

- Custom machining & small-batch manufacturing

- Fastest worldwide export with unbeatable prices

Packaging & Quality Assurance

We ensure the safe delivery of 503 stainless steel fittings with:

- Heavy wooden boxes and steel cradles

- End protectors to prevent damage during shipping

- Full certification package, including material traceability and test reports

FAQ Section

Q: What is the maximum continuous service temperature of 503 fittings?

A: 503 fittings can withstand continuous service up to 980°C.

Q: Are 503 stainless steel fittings magnetic?

A: Yes, 503 stainless steel fittings are magnetic due to their ferritic structure.

Q: Can 503 fittings be welded?

A: Yes, 503 fittings are highly weldable with appropriate filler materials.

Q: Does 503 suffer from sigma-phase embrittlement?

A: No, 503 fittings do not experience sigma-phase embrittlement.

Q: Is 503 suitable for cyclic high-temperature service?

A: Yes, 503 fittings are ideal for cyclic high-temperature environments.

Conclusion + Urgent Call-to-Action

For instant quotes on 503 stainless steel fittings, contact us 24/7 via WhatsApp, email, phone, or live chat. Choose the best supplier for your high-temperature fitting needs.