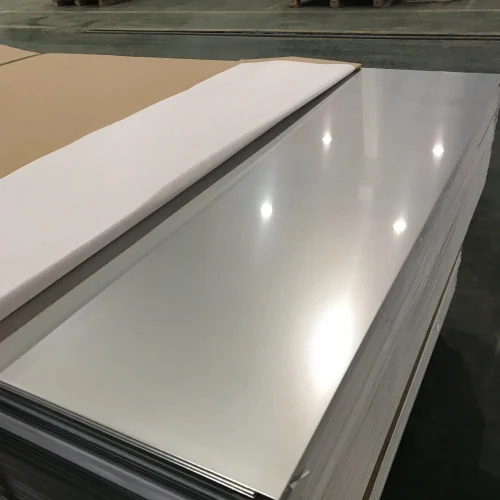

202 Stainless Steel – The Budget-Smart Austenitic Powerhouse That Cuts Costs Without Cutting Performance

202 Stainless Steel is the metallurgical sweet spot engineers reach for when 304 looks too expensive and 201 feels too lean. By replacing up to 4 % nickel with strategic manganese and nitrogen additions, this austenitic grade delivers a stable, non-magnetic lattice that still packs 16–18 % chromium for dependable corrosion resistance. The result is a lower-cost, higher-manganese alloy (UNS S20200) that machines, welds and forms like its premium cousin yet typically saves 8–12 % on raw-material spend. Whether you are bidding on a 10 000 m² façade or prototyping a new line of cookware, 202 Stainless Steel gives you the mechanical muscle and oxidation resistance you need—without the nickel-price volatility that keeps purchasing managers awake at night.

Key Features & Benefits – Why 202 Stainless Steel Outperforms Its Price Tag

Mechanical Muscle

- High tensile strength (≥ 515 MPa) lets you down-gauge by up to 0.1 mm in many panels, trimming weight and freight cost.

- 40 % elongation means deep draws, tight bends and aggressive stampings succeed on the first pass—ideal for complex sink bowls or automotive trim.

Corrosion & Oxidation Resistance

- 17 % Cr + 2 % Mo-free chemistry stops tea-staining in humid warehouses and urban atmospheres; ASTM B117 salt-spray data show 202 Stainless Steel survives 500 h with <5 % red-rust area.

- Non-hardenable austenitic structure stays crack-free in temperatures from –40 °C to 870 °C, so insulation clamps and oven liners last for decades.

Fabrication Friendliness

- Lower work-hardening rate than 301 or 304; reduces tool wear and eliminates intermediate anneals in multi-stage presses.

- Excellent arc-weldability with 308L or 202 filler—no pre-heat, no post-weld stress relief, saving hours on the shop floor.

Cost & Sustainability Edge

- Nickel substitution lowers alloy surcharge; buyers locked into annual contracts often pocket a 10 % saving over 304.

- 100 % recyclable and RoHS compliant, helping OEMs hit eco-design targets without premium-grade spend.

Technical Specifications

| Property (Room Temp) | Typical Value | Standard |

|---|---|---|

| Density | 7.8 g/cm³ | ASTM A240 |

| Melting Range | 1 400 – 1 450 °C | AISI |

| Tensile Strength | ≥ 515 MPa | ASTM A370 |

| Yield Strength (0.2 % offset) | ≥ 275 MPa | ASTM A370 |

| Elongation in 50 mm | ≥ 40 % | ASTM A370 |

| Hardness, HRB | ≤ 95 | ASTM E18 |

| Modulus of Elasticity | 200 GPa | ASTM A666 |

These values satisfy AISI 202 and UNS S20200 limits, ensuring global interchangeability in supply chains governed by ISO 9327-1 or EN 10088-2.

Applications & Use Cases – Where 202 Stainless Steel Shines

Kitchen & Food Equipment

Manufacturers from Mumbai to Monterrey stamp 0.5 mm 202 Stainless Steel into colanders, mixing bowls and electric-kettle bodies. The grade’s stable austenite eliminates post-weld magnetism—critical for induction-compatible cookware—while its chrome level survives constant steam.

Architectural Panels & Elevator Interiors

Because 202 accepts #4 satin and vibration finishes equal to 304, architects specify it for feature walls, column covers and lift cabs. On the 42-storey Nexus Tower project, cladding consultants saved USD 180 000 switching 2 200 sheets from 304 to 202 without compromising the 25-year corrosion warranty.

Automotive Trim & Rail Coaches

202 Stainless Steel withstands UV, road salt and pressure-wash chemicals, making it the default for bus and metro seat frames, luggage racks and window trims. Indian Railways alone consumes 12 000 t annually, cutting carriage weight by 1.2 t per coach while meeting 15-year service life.

Furniture & Store Fixtures

Bright-annealed (BA) 202 mirrors light like chrome but resists fingerprints—perfect for retail display legs, shelving uprights and adjustable desk frames. The lower nickel content also avoids skin-contact dermatitis concerns for EU REACH compliance.

Tubular & Structural Sections

With yield strength 20 % higher than 201, 202 Stainless Steel is extruded into handrails, balustrades and lightweight space frames. Its superior impact toughness (-40 °C Charpy 150 J) satisfies pedestrian-bridge codes without the cost jump to duplex grades.

Comparison with Other Grades – 202 vs 201, 304 & 430

| Grade | Nickel % | Corrosion Resistance | Relative Cost | Typical Uses |

|---|---|---|---|---|

| AISI 202 | 4 % | Medium | Low | Cookware, façades, rail trim |

| AISI 201 | 3.5 % | Low-Medium | Low | Hose clamps, table legs |

| AISI 304 | 8 % | High | Medium | Food tanks, chemical pipes |

| AISI 430 | 0 % | Low | Lowest | Dishwasher panels, trim |

Pros: 202 Stainless Steel bridges the gap between 201 and 304, giving better pitting resistance than 201 while staying price-competitive.

Cons: In marine splash zones or chloride >1 000 ppm, specify 304 or 316; 202 can suffer crevice corrosion after prolonged exposure.

Manufacturing Process & Quality Assurance

We melt 202 Stainless Steel in a 120 t electric-arc furnace, argon-oxygen decarburise for exact chemistry, then continuous-cast into 200 mm slabs. Hot rolling to 2.0 mm is followed by annealing at 1 050 °C and pickling in mixed acid to remove oxide. Finish options include 2B for painting, BA for mirror reflection, and No. 4 linear polish. Every coil is tested to ISO 9001:2015 with PMI (positive material identification), ICP spectroscopy for Mn, Cr, Ni, and ASTM A262 Practice A intergranular corrosion. Mill test certificates report yield, tensile, elongation and Rockwell hardness—data you can upload straight into your PPAP file.

Maintenance & Care Tips

Clean 202 Stainless Steel with mild detergent and warm water; chloride-containing bleaches are the enemy. Rinse welds and corners thoroughly, then wipe dry to prevent water spots. For external façades, an annual wipe-down with 1 % nitric acid restores the passive film and keeps tea-staining at bay. Store sheets vertically in a dry warehouse; use plastic separators to avoid galvanic coupling with carbon steel.

Frequently Asked Questions

Q: Is 202 Stainless Steel food-grade?

A: Yes—its 18 % Cr meets EU 1935/2004 and FDA 21 CFR requirements for neutral pH food contact; however, for high-chloride sauces specify 304L.

Q: How does 202 compare to 304 in rust resistance?

A: In rural or mild urban atmospheres the difference is negligible; within 500 m of coastlines or in chemical plants, upgrade to 304 or 316.

Q: Can I polish 202 to a mirror?

A: Absolutely—start with 120 grit and step to 800, then green compound; BA substrate achieves 520 gloss units, equal to 304.

Ready to slash material cost without sacrificing quality? Contact us now for custom slit coils, sheets or circles in 202 Stainless Steel—mill-direct pricing, global shipping, and technical support included.