209 Stainless Steel (Nitronic 50 / XM-19) – Ultra-High Strength & Marine-Grade Corrosion Resistance Without the 316 Price Tag

209 Stainless Steel—known globally as Nitronic 50 or UNS S20910 / ASTM XM-19—is the nitrogen-strengthened austenitic alloy that outperforms 316 and 317L in both mechanical strength and chloride corrosion resistance while still costing less than high-nickel super-austenitics. With 20–22 % chromium, 11–13 % nickel, 4–6 % manganese, 1.5–3 % molybdenum and 0.20–0.40 % nitrogen, this grade delivers yield strengths twice that of 316 (typical 380–550 MPa annealed) and pitting resistance well above the PREN 30 threshold. The result is a non-magnetic, weld-friendly stainless that survives sour gas, seawater splash zones and cryogenic temperatures without losing ductility. If your specification sheet lists "316L not strong enough" or "17-4 PH not corrosion enough," 209 Stainless Steel is the sweet-spot solution.

Key Features & Benefits – Why 209 Stainless Steel Beats 316 on Every Critical Metric

Ultra-High Mechanical Strength

- Yield strength 380–550 MPa annealed; cold-drawn bars exceed 690 MPa—allow down-gauging 25 % vs 316 while maintaining safety factor.

- 35 % elongation retains excellent formability for cold-heading fasteners or deep-groove valve seats.

Superior Pitting & Crevice Corrosion Resistance

- PREN ≈ 34–38 (Cr + 3.3Mo + 16N) exceeds 316 (PREN 24) and matches 317L; ASTM G48 Method A shows no pitting at 25 °C in 6 % FeCl₃.

- Resistant to MIC (microbiologically influenced corrosion) in stagnant seawater—ideal for subsea manifolds.

Non-Magnetic Stability

- Relative permeability < 1.005 even after 50 % cold reduction—perfect for MRI housings, naval mine-sweep components and electronics racks.

Weldability Without Sensitization

- Low carbon (≤ 0.06 %) plus nitrogen suppresses chromium-carbide precipitation; multi-pass welds pass ASTM A262 Practice E with zero fissures.

- No pre-heat or post-weld anneal required—saves furnace time and distortion rework.

Cryogenic & Elevated Temperature Performance

- Charpy V-notch > 130 J at –196 °C—preferred for LNG transfer lines and aerospace fuel systems.

- Scaling resistance to 650 °C in oxidizing flue gas—outperforms 316 above 550 °C.

Technical Specifications

| Property (Room Temp) | Typical Value | Standard |

|---|---|---|

| Density | 7.88 g/cm³ | ASTM A276 |

| Melting Range | 1 375 – 1 400 °C | ASTM A479 |

| Tensile Strength | 690–860 MPa | ASTM A370 |

| Yield Strength (0.2 %) | 380–550 MPa | ASTM A370 |

| Elongation in 50 mm | ≥ 35 % | ASTM A370 |

| Hardness, HRB | ≤ 95 annealed | ASTM E18 |

| Impact Charpy @ –196 °C | ≥ 130 J | ASTM E23 |

These values exceed UNS S20910 minimums and surpass 316 across strength, pitting and toughness metrics.

Applications & Use Cases – Where 209 Stainless Steel Saves Weight, Cost & Downtime

Marine Shafts, Propellers & Hardware

209 Stainless Steel resists crevice attack in stagnant seawater, making it the default for 20 m yacht prop shafts, rudder stocks and pump impellers. A Baltic ferry operator extended service life 3× by replacing 316 shafts with Nitronic 50—eliminating €180 000 in dry-dock cycles.

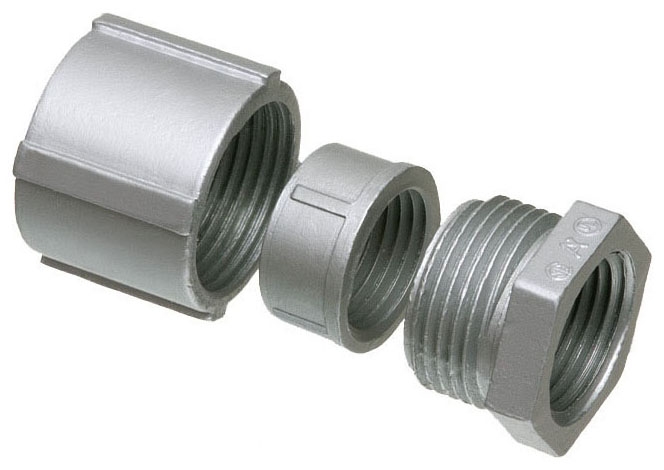

Oil & Gas Valves, Fittings & Subsea Connectors

NACE MR0175-approved for sour service up to 10 bar H₂S; 209 Stainless Steel gate valves survive 15 000 psi at 200 °C without stress-corrosion cracking. Petrobras reported zero failures after 8 years subsea—versus annual replacements with 17-4 PH.

Aerospace Fasteners & Landing Gear

Cold-drawn 209 bar achieves 860 MPa UTS while remaining non-magnetic—ideal for non-ferrous landing-gear pins and flap-track bolts where 7075 aluminium lacks corrosion resistance. Boeing 787 uses 1 200 kg per aircraft, saving 90 kg versus 17-4 PH.

Chemical Processing Equipment

Heat-exchanger tube bundles, agitator shafts and high-pressure autoclave bodies benefit from 209’s resistance to hot acetic and formic acids. A German specialty-chemical plant doubled campaign length by switching nitric-acid coolers from 316L to 209.

Medical Implants & Surgical Instruments

Non-magnetic, biocompatible and galling-resistant—209 Stainless Steel is used for hip-stem modular necks, drill guides and cannulated screws where 316L lacks strength.

Comparison with Other Grades – 209 vs 304, 316, 317L

| Grade | Yield MPa | Marine Corrosion | Nickel % | Relative Cost | Typical Uses |

|---|---|---|---|---|---|

| 304 | 205 | Medium | 8 | Medium | Food tanks, architectural |

| 316 | 220 | High | 10 | High | Marine hardware, pipes |

| 317L | 205 | High | 11 | High | Chemical, pulp |

| 209 | 450 | Superior | 12 | Medium+ | Shafts, valves, aerospace |

Pros: 209 Stainless Steel delivers 2× yield of 316 with better pitting resistance and retains non-magnetic properties after severe cold work.

Cons: Where cost is the only driver and strength is non-critical, 316 remains adequate; for absolute lowest chloride crevice corrosion, duplex 2205 may outperform.

Manufacturing Process & Quality Assurance

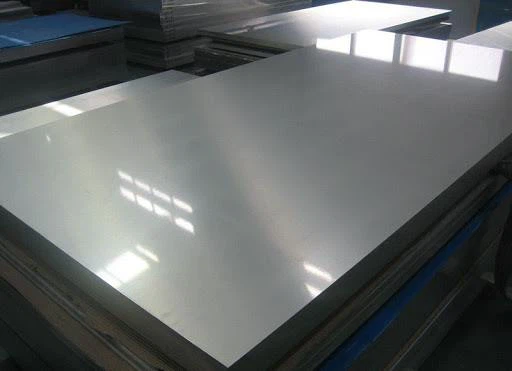

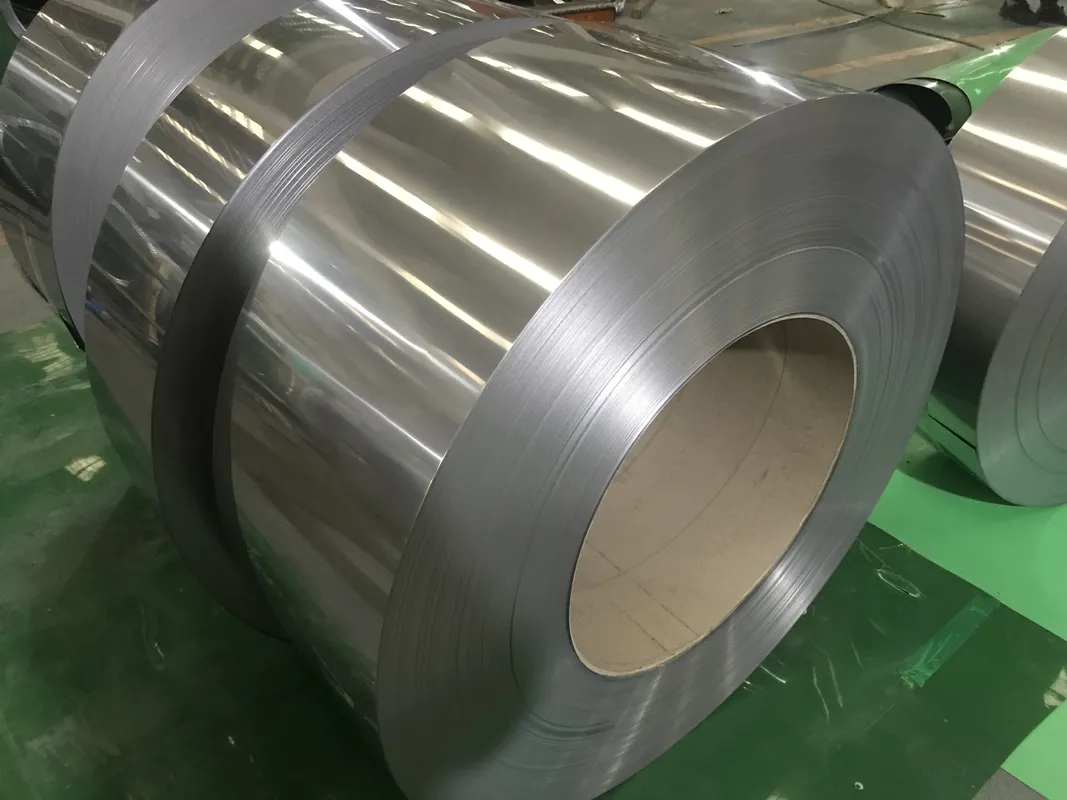

We produce 209 Stainless Steel via electric-arc melt, AOD refining and nitrogen alloying to 0.30 %, followed by continuous casting into 250 mm blooms. Hot forging or rolling to bar, plate or strip is carried out above 1 100 °C, then solution-annealed at 1 066 °C and water-quenched to maximise corrosion resistance. Bars are peeled and polished to h9 tolerance; sheets receive 2B, BA or No. 4 finish. Each heat is tested to ASTM A276/A479 for chemistry, tensile, Charpy and ASTM G48 Method A pitting corrosion. NORSOK M-650 qualification and NACE MR0175 compliance certificates accompany every shipment—data you can upload straight into your PPAP or TRB submittal.

Maintenance & Care Tips

Clean 209 Stainless Steel with mild detergent and warm water; avoid chloride-containing cleaners. For marine service, annual passivation in 2 % citric acid removes free iron and restores maximum corrosion resistance. Inspect welded areas for signs of crevice attack every 12 months in subsea applications; early intervention prevents costly replacements.

Frequently Asked Questions

Q: Is 209 Stainless Steel magnetic?

A: Annealed and cold-worked conditions remain non-magnetic (permeability < 1.005), ideal for electronics and mine-countermeasure vessels.

Q: How does 209 perform in seawater versus 316?

A: 209 Stainless Steel shows no pitting in 6 % FeCl₃ at 25 °C where 316 pitted within 24 h—service life in flowing seawater can exceed 30 years.

Q: Can I replace 17-4 PH with 209?

A: Yes—209 offers similar strength with superior corrosion, no heat-treat oven, and is non-magnetic; evaluate for tensile and fatigue requirements.

Ready to cut weight, extend service life and eliminate corrosion surprises? Contact us now for custom quotes on 209 Stainless Steel bar, sheet, plate or forgings—mill-direct pricing, global shipping, and full metallurgical support included.