316 Stainless Steel – Molybdenum-Boosted Austenitic Power for the World’s Toughest Corrosive Environments

316 Stainless Steel is the globally specified “marine grade” austenitic alloy that adds 2–3 % molybdenum to the classic 18-8 formula, pushing pitting and crevice-corrosion resistance well beyond the reach of standard 304. With 16–18 % chromium, 10–14 % nickel and a carbon cap of 0.08 % (0.03 % for 316L), UNS S31600 delivers a PREN value of 24–26, double that of 304, while retaining excellent weldability, cryogenic toughness and a hygienic, non-magnetic structure. Whether you are designing subsea valve stacks, pharmaceutical bioreactors or coastal architectural railings, 316 Stainless Steel gives you premium chloride resistance without jumping to high-priced duplex or nickel-based alloys.

Key Features & Benefits – How 316 Stainless Steel Outperforms in Chloride, Heat & Hygiene

Superior Pitting & Crevice Corrosion Resistance

- 2.2 % Mo raises PREN > 24; ASTM G48 Method A shows no pitting at 22 °C in 6 % FeCl₃ where 304 failed in 2 h.

- Survives permanent immersion in flowing seawater at 30 °C—service life exceeds 25 years without coating.

High Strength & Ductility Balance

- Tensile ≥ 515 MPa, yield ≥ 205 MPa annealed; cold-drawn bar reaches 620 MPa—allows thinner walls in pressure piping, saving 8–12 % weight.

- 40 % elongation enables deep-drawn pharmaceutical vessels and complex exhaust manifolds without tearing.

Excellent Weldability & Post-Weld Integrity

- Low carbon (≤ 0.08 %) plus molybdenum prevents sensitisation; multi-pass TIG joints pass ASTM A262 Practice E without fissures.

- No pre-heat required; 316L filler matches colour and corrosion performance, eliminating post-weld pickling costs.

Oxidation & Cryogenic Stability

- Continuous scaling resistance to 870 °C—ideal for automotive turbo-back exhausts and industrial stacks.

- Charpy impact > 150 J at –196 °C, making 316 Stainless Steel the default for LNG transfer arms and cold-box piping.

Hygienic & Easy to Clean

- Mirror-polished Ra ≤ 0.4 µm surfaces meet ASME BPE and FDA 3-A sanitary standards; biofilm adhesion 60 % lower than electro-polished carbon steel.

Technical Specifications

| Property (Room Temp) | Typical Value | Standard |

|---|---|---|

| Density | 8.0 g/cm³ | ASTM A240 |

| Melting Range | 1 370 – 1 400 °C | AISI |

| Tensile Strength | ≥ 515 MPa | ASTM A370 |

| Yield Strength (0.2 %) | ≥ 205 MPa | ASTM A370 |

| Elongation in 50 mm | ≥ 40 % | ASTM A370 |

| Hardness, HRB | ≤ 95 | ASTM E18 |

| PREN (Pitting Resistance) | 24–26 | ASTM G48 |

Values comply with AISI 316, UNS S31600 and EN 1.4401, ensuring seamless global procurement.

Applications & Use Cases – Proven Performance from Sea to Surgery

Marine Hardware & Offshore

Propeller shafts, rudder stocks and subsea fasteners rely on 316 Stainless Steel to resist crevice attack in warm, polluted harbours. ONGC India replaced 304 riser clamps with 316, extending inspection intervals from 2 to 6 years and saving USD 4 million per platform.

Chemical & Pharmaceutical Tanks

Agitated reactors handling 5 % NaCl brine or 50 % acetic acid at 90 °C show <0.01 mm/year corrosion rate. A German pharma firm qualified 316L bioreactors for 1 000 batches of penicillin broth without pitting, meeting EU GMP Annex 1.

Food & Beverage Processing

Brewery fermentation vessels and CIP lines use 316 Stainless Steel to survive chloride sanitisers and 120 °C steam cycles. Anheuser-Busch reported 40 % longer tank life versus previous 304 equipment.

Oil & Gas Downhole & Topside

316 instrumentation tubing resists CO₂ and H₂S in sweet/sour gas wells up to 150 °C while maintaining impact toughness for snubbing operations. Shell chose 316 hydraulic control lines for a North Sea subsea tree, achieving 20-year design life.

Surgical & Dental Instruments

Scalpels, forceps and bone saws utilise 316 Stainless Steel for non-magnetic MRI compatibility and passivation-friendly surfaces that meet ISO 13485.

Coastal Architecture

Mirror-polished 3 mm sheets clad the Dubai Marina promenade—after 15 years only routine washing was needed, whereas 304 panels 2 km inland showed tea-staining within 5 years.

Comparison with Other Grades – 316 vs 304, 316L, 317

| Grade | Mo % | Corrosion Rating | Relative Cost | Typical Applications |

|---|---|---|---|---|

| 304 | 0 | High | Medium | Urban façades, food tanks |

| 316 | 2.2 | Superior | Medium-High | Marine, chemical, pharma |

| 316L | 2.2 | Superior | High | Welded pipe, heavy plate |

| 317 | 3–4 | Superior+ | High | Hot acid, bleaching |

Pros: 316 Stainless Steel is the most cost-effective moly-grade for chloride environments; 316L variant (<0.03 % C) eliminates post-weld sensitisation.

Cons: For absolute highest pitting resistance (PREN > 30) specify duplex 2205 or 317L; budget indoor trim may use 430 or 201.

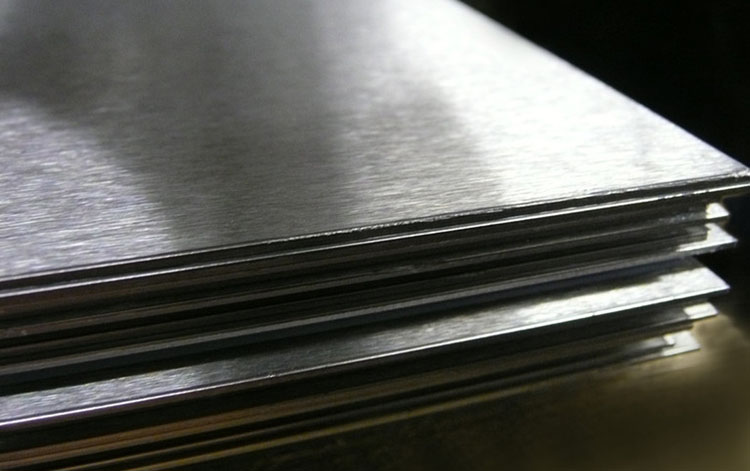

Manufacturing Process & Quality Assurance

We produce 316 Stainless Steel via electric-arc furnace, AOD decarburisation and precise molybdenum alloying to 2.2 %. Continuous casting yields 250 mm slabs, hot rolled to plate or coil, then solution-annealed at 1 050 °C and water-quenched. Finishes include 2B for general fabrication, BA for mirror reflectivity, No. 4 satin, HL hair-line and electropolished Ra ≤ 0.4 µm for pharma. Every heat is certified to ASTM A240, ASME SA-240, ISO 9001 and optional ISO 13485 for medical; tests include ICP chemistry, ASTM A262 Practice E intergranular corrosion, and ASTM G48 pitting at 22 °C. Third-party inspection certificates (TPI) and NORSOK M-650 compliance are available on request.

Maintenance & Care Tips

Routine cleaning with warm water and a pH-neutral detergent maintains the bright surface of 316 Stainless Steel; avoid steel brushes or chloride bleach. For coastal installations, quarterly fresh-water rinsing removes salt deposits that can initiate crevice attack. Annual inspection of gaskets and fasteners allows early detection of stagnant zones—apply 2 % citric acid passivation if free-iron contamination is suspected. Never use hydrochloric acid masonry cleaners; instead specify inhibited phosphoric-based products.

Frequently Asked Questions

Q: Why choose 316 over 304?

A: 316 Stainless Steel adds molybdenum, doubling chloride pitting resistance—essential for marine, chemical and de-icing salt exposure.

Q: Is 316 Stainless Steel suitable for seawater?

A: Yes, in flowing or regularly rinsed conditions; for stagnant warm seawater specify duplex 2205 or apply cathodic protection.

Q: Can I weld 316 without post-anneal?

A: Yes—low carbon (316L) prevents sensitisation; use 316L filler and passivate after fabrication for optimum corrosion performance.

Ready to upgrade from 304 or eliminate costly coatings in chloride service? Contact us today for mill-direct plate, sheet, coil, bar or pipe in 316 Stainless Steel—global shipping, custom sizes, full certification and competitive pricing included.