410 Stainless Steel Sheet – The Most Cost-Effective Martensitic Grade for High-Strength & Wear Resistance

When your project demands strength over maximum corrosion resistance, 410 Stainless Steel Sheet is the only logical choice. This martensitic grade delivers up to 3× the yield strength of 304 after heat treatment, excellent wear resistance, and the lowest price of any stainless grade—all while remaining fully magnetic. From cutlery blades and surgical instruments to pump shafts, turbine blades, and mining wear plates, 410 stainless steel sheet offers the best strength-to-cost ratio in the stainless world—making it the first choice for engineers, knife makers, and global traders who prioritize performance and economy.

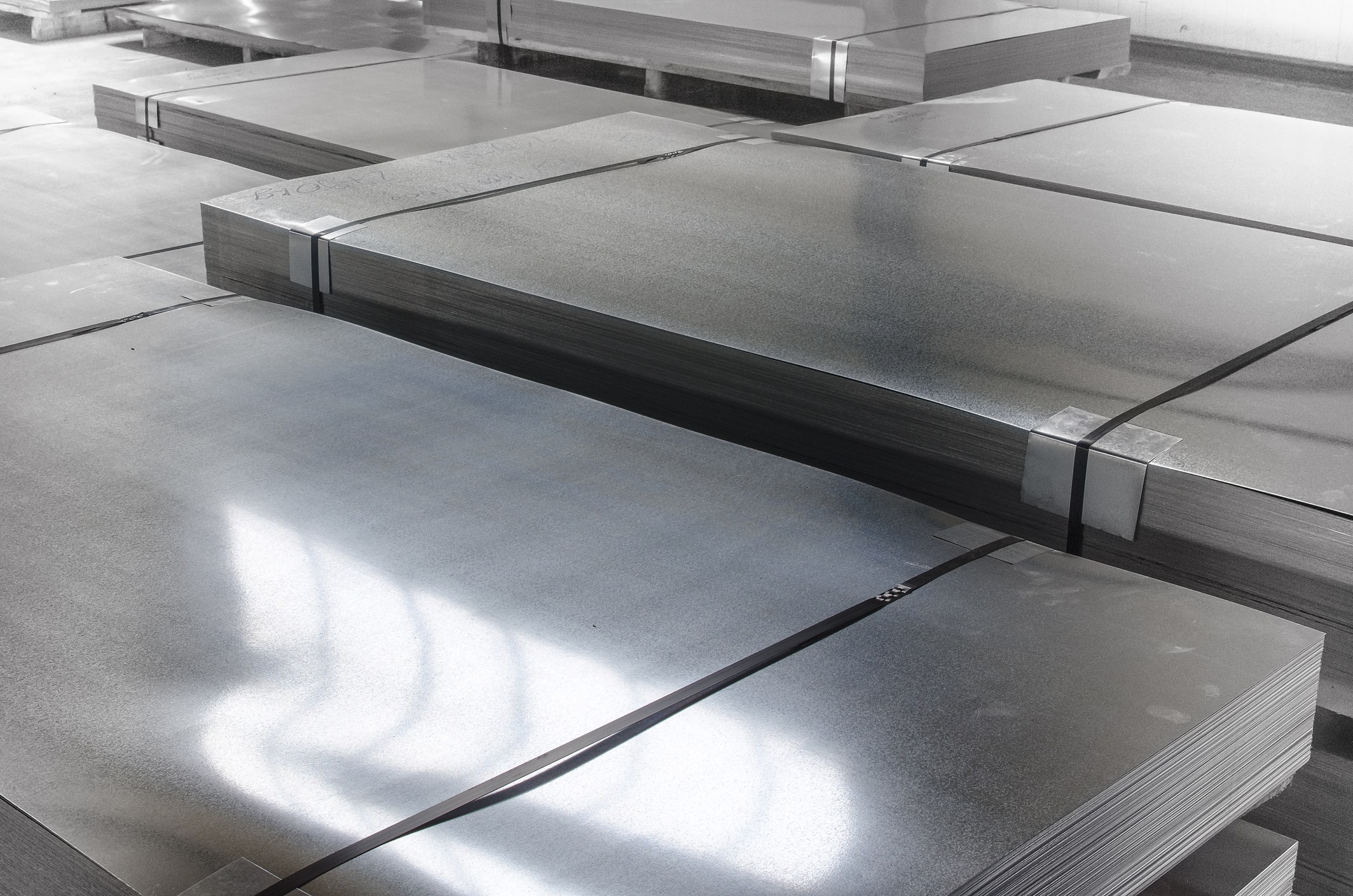

Caption: 410 BA Stainless Steel Sheet – Premium Mirror Finish, Direct from China's Top 410 Cold Rolled Stainless Steel Sheet Company

Caption: 410 BA Stainless Steel Sheet – Premium Mirror Finish, Direct from China's Top 410 Cold Rolled Stainless Steel Sheet CompanyKey Features & Benefits

- Martensitic structure – up to 3× yield strength vs 304 after quench & temper

- Lowest stainless price – 30–40 % cheaper than 304

- Excellent wear resistance – ideal for cutting edges, shafts, fasteners

- Fully magnetic – suitable for induction heating & sensor applications

- Full heat-treatable – hardness up to 50 HRC after tempering

- Wide finish range – 410 BA stainless steel sheet, 2B, No.1, polished

- Full compliance – ASTM A240, A480, EN 10088-2, PED 2014/68/EU

Technical Specifications

Table 1 – Chemical Composition (ASTM A240)

| Element | 410 % | 420 % | 304 % |

|---|---|---|---|

| Cr | 11.5–13.5 | 12.0–14.0 | 18.0–20.0 |

| Ni | ≤0.75 | ≤0.75 | 8.0–10.5 |

| C | ≤0.15 | ≤0.15–0.40 | ≤0.08 |

| Mn | ≤1.00 | ≤1.00 | ≤2.00 |

| Fe | Balance | Balance | Balance |

Table 2 – Mechanical Properties (ASTM A240)

| Condition | Yield MPa | Tensile MPa | Hardness HB | Machinability |

|---|---|---|---|---|

| Annealed | ≥205 | ≥450 | ≤200 | 70 % |

| Q&T 500 °C | ≥1000 | ≥1200 | ≤380 | 50 % |

| Q&T 300 °C | ≥1500 | ≥1800 | ≤500 | 40 % |

Quench & temper data typical for 3 mm sheet.

Size & Finish Range

410 Cold Rolled Stainless Steel Sheet

| Thickness (mm) | Width (mm) | Finish Options | Standard |

|---|---|---|---|

| 0.3–1.0 | 1000–1250 | 2B, BA, No.4, 8K | ASTM A240 |

| 1.0–3.0 | 1000–1524 | 2B, No.4, HL | ASTM A240 |

| 3.0–6.0 | 1000–2000 | No.4, HL | ASTM A240 |

410 Hot Rolled Stainless Steel Sheet

| Thickness (mm) | Width (mm) | Finish Options | Standard |

|---|---|---|---|

| 3.0–12 | 1250–2000 | No.1, pickled | ASTM A240 |

| 12–50 | 1500–2500 | No.1, HRAP | ASTM A240 |

| 50–100 | 1500–3000 | No.1, forged | ASTM A240 |

Custom lengths 1000–12000 mm, cut-to-size available.

Product Range & Market Info

As the largest 410 hot rolled stainless steel sheet manufacturer & 410 hot rolled stainless steel sheet wholesaler in China, we operate a 400 000 t/year Steckel mill with in-house quenching & tempering lines dedicated to 410 stainless steel sheet production. Our 250 000 m² facility keeps 60 000 t of ready stock in Shanghai and Houston, ensuring immediate availability for global knife makers and valve manufacturers. Whether you need one coil of 2 mm × 1219 mm or a full plate of 50 mm × 2500 mm, our mill-direct 410 cold rolled stainless steel sheet price and ISO-approved quality give you the competitive edge. Contact our export team today for the most updated quotation and downloadable 3.1 MTC.

Specialty products include complete 410 BA stainless steel sheet – mirror-finish Ra ≤0.2 µm, manufactured under ASTM A240.

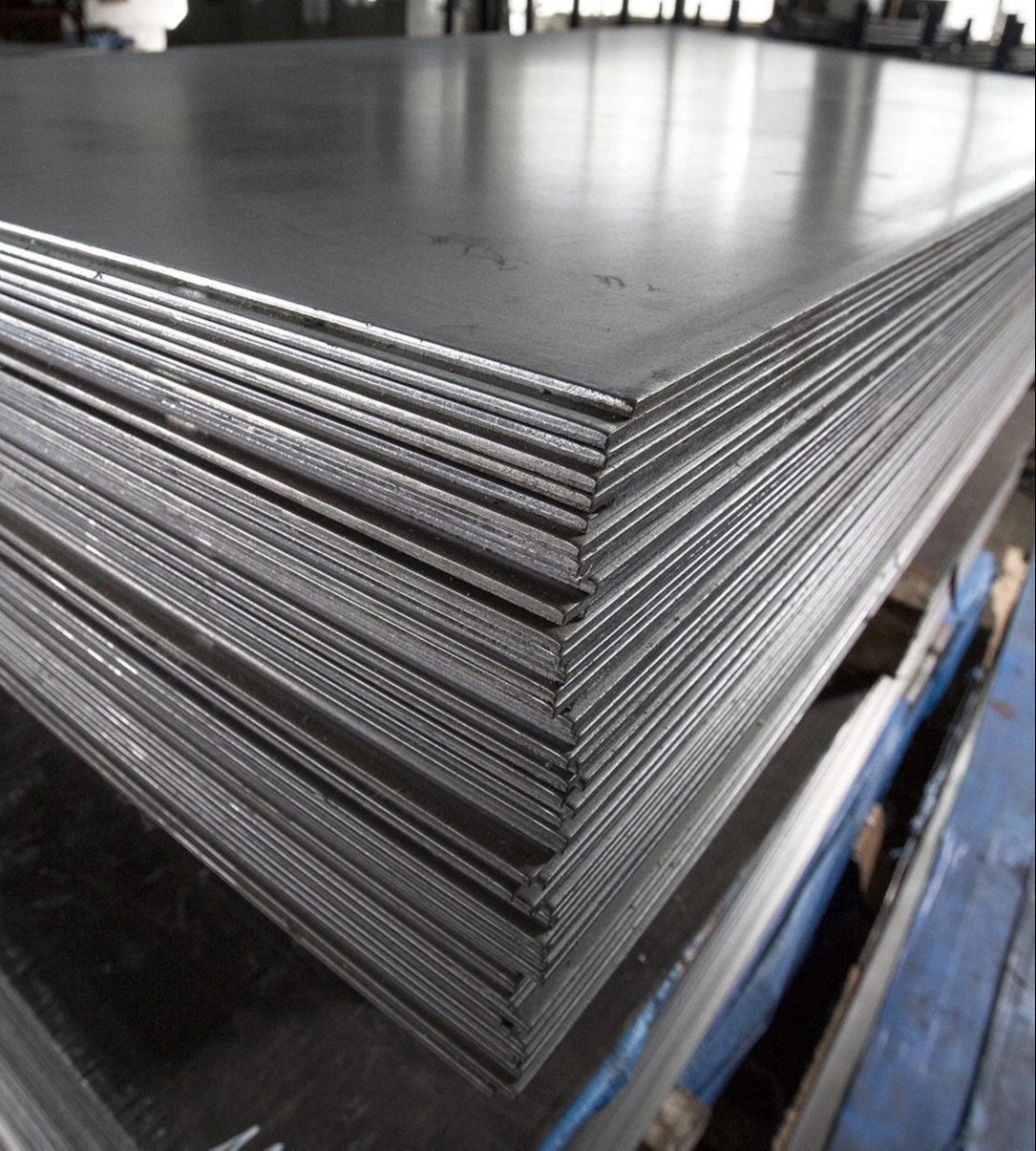

Caption: 410 Hot Rolled Stainless Steel Sheet – Mill-Direct from Leading 410 Hot Rolled Stainless Steel Sheet Manufacturer & Wholesaler

Caption: 410 Hot Rolled Stainless Steel Sheet – Mill-Direct from Leading 410 Hot Rolled Stainless Steel Sheet Manufacturer & WholesalerMain Applications

- Cutlery & kitchen knives – blades, scissors, cleavers

- Surgical instruments – scalpels, forceps, clamps

- Valves & pump parts – shafts, plungers, seats

- Turbine blades – steam, gas, hydro

- Fasteners & bolts – high-strength, magnetic

- Automotive trim – door sills, exhaust brackets

- Press plates – hot stamping, embossing

- Mining equipment – wear plates, crusher liners

- Shafts & wear plates – conveyors, mixers

Why Choose Us – Martensitic Specialist

- Mill-direct pricing – 30–40 % cheaper than 304

- 400 000 tons annual martensitic capacity – 5-day lead time

- ISO 9001 & PED certified – EN 10204 3.1 & 3.2 MTC supplied

- In-house quenching & tempering line – hardness up to 50 HRC

- Same-day cutting & polishing – tolerances ±0.2 mm, mirror finish

- Real-time stock portal – 24/7 visibility for 410 cold rolled stainless steel sheet price

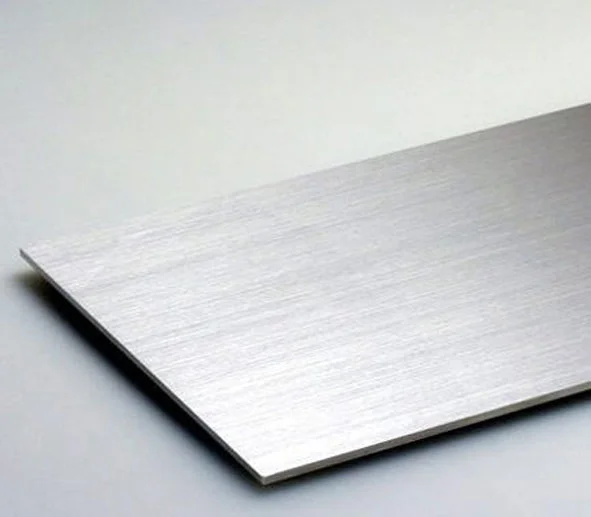

Caption: Massive Ready Stock & Most Competitive 410 Cold Rolled Stainless Steel Sheet Price – Same-Day Shipping Worldwide

Caption: Massive Ready Stock & Most Competitive 410 Cold Rolled Stainless Steel Sheet Price – Same-Day Shipping WorldwideGrade Comparison Table: 410 vs 420 vs 430 vs 304 vs 3CR12

| Grade | Cr % | Ni % | Yield MPa (Q&T) | Relative Cost | Best Use |

|---|---|---|---|---|---|

| 410 | 11.5–13.5 | ≤0.75 | ≥1000 | 0.6× | Cutlery, valves |

| 420 | 12–14 | ≤0.75 | ≥1200 | 0.7× | Surgical, blades |

| 430 | 16–18 | 0 | ≥205 | 0.7× | Indoor, magnetic |

| 304 | 18–20 | 8–10.5 | ≥205 | 1.0× (base) | General corrosion |

| 3CR12 | 12 | 0.5 | ≥280 | 0.8× | Mine wear |

FAQ – 410 Stainless Steel Sheet

-

What is the latest 410 cold rolled stainless steel sheet price?

Mill-direct FOB China USD 1.80–2.20/kg depending on nickel surcharge; fixed for 48 h. -

Heat treatment guide?

Quench 980–1050 °C, oil or air; temper 200–600 °C to achieve 30–50 HRC. -

Hardness after tempering?

Up to 50 HRC at 300 °C; decreases above 500 °C for toughness. -

Stock thickness range?

410 cold rolled stainless steel sheet 0.3–6 mm, 410 hot rolled stainless steel sheet 3–100 mm – 60 000 t ready. -

BA vs 2B finish?

410 BA stainless steel sheet is bright annealed mirror-like; 2B is matte cold-rolled. -

Minimum order quantity?

One sheet for stock sizes; full container (≈25 t) for mill-direct custom thickness. -

Which certificates accompany the shipment?

EN 10204 3.1/3.2 MTC, ISO 9001, PED 2014/68/EU, and third-party inspection (SGS/TÜV/BV). -

Do you export worldwide?

Yes, to 80+ countries including UK, Germany, India, UAE, South Korea, and Australia.

Call-to-Action

Stop paying nickel premiums. Contact the largest 410 hot rolled stainless steel sheet manufacturer today for the latest 410 cold rolled stainless steel sheet price, immediate access to massive 410 stainless steel sheet stock, and same-day cutting of 410 BA stainless steel sheet or any thickness.