504 Stainless Steel Sheet: High-Temperature Performance & Cost-Effective Solution

Meta Description

Discover 504 stainless steel sheet with exceptional oxidation resistance up to 1000°C, ideal for furnace linings, heat shields, and more. Reliable 504 stainless steel sheet suppliers offering competitive prices.

Introduction

504 stainless steel sheet is a ferritic stainless steel designed for high-performance applications requiring exceptional oxidation resistance and thermal stability at elevated temperatures. Capable of withstanding temperatures up to 1000°C, this material offers outstanding resistance to scaling, making it an ideal choice for industries such as furnace manufacturing, heat-treatment plants, and petrochemical refineries. Compared to austenitic alloys like 310 and 309, 504 stainless steel provides a cost-effective solution for high-temperature environments where oxidation and thermal cycling are prevalent.

With its ferritic structure, 504 stainless steel sheet offers superior thermal fatigue resistance and ensures long-lasting durability even in harsh conditions. It serves as an ideal alternative to more expensive austenitic grades while maintaining high resistance to thermal cycling and thermal shock. Furthermore, 504 stainless steel is a preferred choice for applications where weldability and formability are essential, without compromising performance in high-heat environments.

This cost-effective stainless steel sheet provides a versatile solution for a wide range of industries, including furnace linings, heat shields, and kiln components. Let's explore the properties, chemical composition, and applications of 504 stainless steel in more detail.

Product Overview & Key Advantages

- Exceptional Oxidation Resistance: 504 stainless steel sheet provides outstanding oxidation resistance at temperatures up to 1000°C, making it perfect for high-temperature applications in furnaces and kilns.

- Ferritic Structure for High Thermal Stability: The ferritic structure of 504 stainless steel ensures superior thermal stability and thermal fatigue resistance, even in extreme temperature fluctuations.

- Cost-Effective Alternative to Austenitic Alloys: 504 stainless steel is a cost-effective solution compared to 310 or 309 austenitic grades, providing high performance at a more competitive price point.

- Good Weldability: 504 stainless steel offers excellent weldability with the right filler material, making it suitable for a variety of fabrication processes.

- Thermal Fatigue Resistance: This grade of stainless steel is ideal for cyclic high-temperature applications, such as heat exchangers and exhaust systems, thanks to its high thermal fatigue resistance.

Key Advantages:

- Outstanding oxidation resistance up to 1000°C.

- Ferritic structure ensures thermal stability and resistance to thermal shock.

- Cost-effective alternative to austenitic alloys like 310 and 309.

- Good weldability with the proper filler.

- Ideal for high-temperature applications requiring thermal fatigue resistance.

Chemical Composition Table

| Element | 504 Stainless Steel |

|---|---|

| Carbon (C) | ≤ 0.05% |

| Chromium (Cr) | 4.5–6.0% |

| Nickel (Ni) | ≤ 0.75% |

| Manganese (Mn) | ≤ 1.0% |

| Silicon (Si) | 1.0–2.0% |

| Molybdenum (Mo) | 0.25–1.0% |

| Niobium (Nb) | ≤ 0.05% |

| Phosphorus (P) | ≤ 0.04% |

| Sulfur (S) | ≤ 0.03% |

| Iron (Fe) | Balance |

Mechanical Properties Table

| Property | 504 Stainless Steel | 410 Stainless Steel | 430 Stainless Steel |

|---|---|---|---|

| Tensile Strength (MPa) | 485–600 | 485–690 | 480–600 |

| Yield Strength (MPa) | 275–410 | 300–450 | 280–380 |

| Elongation (%) | 20–30 | 15–25 | 18–28 |

| Hardness (Rockwell B) | 85–95 | 90–100 | 90–100 |

| Impact Strength (J) | 25–35 | 20–30 | 25–35 |

Physical Properties & Oxidation Resistance Table

| Property | 504 Stainless Steel |

|---|---|

| Magnetic | Yes |

| Thermal Conductivity | 25.5 W/m·K |

| Thermal Expansion | 11.0 µm/m·°C |

| Density | 7.75 g/cm³ |

| Max Service Temperature | 1000°C |

| Oxidation Resistance | Excellent, up to 1000°C |

504 vs 502 vs 410 vs 430 vs 304 vs 310 Sheet Comparison Table

| Property | 504 Stainless Steel | 502 Stainless Steel | 410 Stainless Steel | 430 Stainless Steel | 304 Stainless Steel | 310 Stainless Steel |

|---|---|---|---|---|---|---|

| Max Service Temperature | 1000°C | 980°C | 650°C | 870°C | 870°C | 1150°C |

| Oxidation Resistance | Excellent | Excellent | Moderate | Good | Excellent | Excellent |

| Cost | Low | Low | Low | Medium | High | High |

| Weldability | Good | Good | Fair | Good | Excellent | Good |

| Formability | Good | Good | Moderate | Good | Excellent | Excellent |

Available Specifications Table

| Thickness | Width | Length | Finish |

|---|---|---|---|

| 0.5–100 mm | 1000–2500 mm | Up to 12000 mm | 2B, No.1 Hot Rolled, Pickled, Polished, Brushed |

High-Temperature Performance Guide

504 stainless steel sheet is designed for continuous service at temperatures up to 1000°C, providing outstanding resistance to scaling and oxidation. For applications involving high-temperature oxidation, 504 stainless steel sheet maintains high strength and formability even after extended exposure. Its thermal stability makes it an ideal choice for furnaces, heat exchangers, and thermal processing trays.

- Continuous service limit: 1000°C

- Intermittent service limit: 1100°C

- Recommended annealing temperature: 800–850°C

Major Applications

- Furnace Linings: 504 stainless steel sheet is widely used in furnace linings for its oxidation resistance and thermal fatigue resistance.

- Heat Shields & Boiler Baffles: Ideal for heat shields and boiler baffles in high-temperature systems.

- Kiln Components & Recuperators: Used in kiln components, recuperators, and thermal processing trays for industries like ceramics and petrochemicals.

- Exhaust Systems: Perfect for automotive exhaust systems and petrochemical heater tubes exposed to high temperatures.

- Glass Molds & High-Temperature Ducting: Suitable for glass molds and high-temperature ducting due to its thermal cycling resistance.

- Incinerator Parts: Ideal for incinerator components exposed to extreme heat.

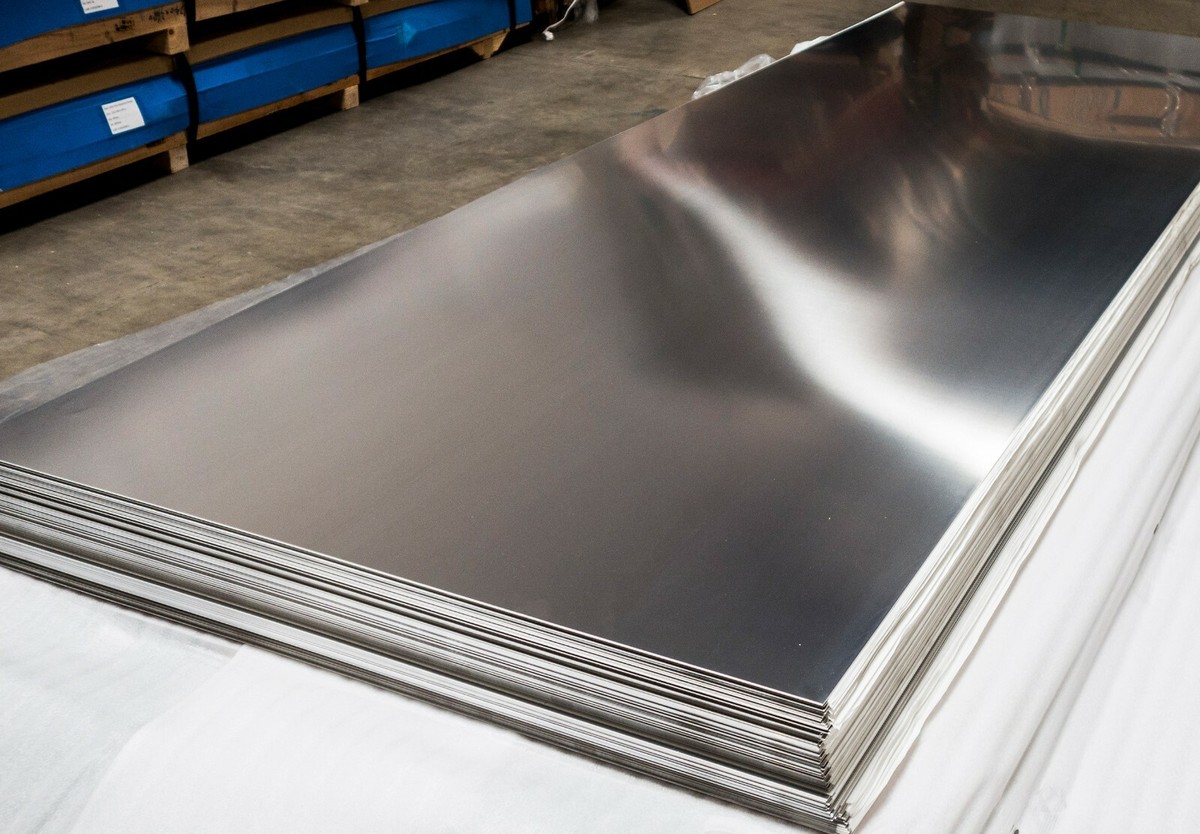

Product Images

Hot-rolled No.1 finish 504 stainless steel sheet stacked in warehouse

Professional infographic 504 stainless steel sheet data sheet + oxidation resistance curve up to 1100°C

Real-application collage – 504 sheets used in furnace linings, heat shields, recuperator components, and high-temperature thermal trays

Why We Are the Best 504 Stainless Steel Sheet Distributor

As the leading global supplier of 504 stainless steel sheet, we offer a large ready stock of thick 504 plates, direct mill relationships, and full EN 10204 3.1/3.2 certificates. With ultrasonic testing, precision cutting, and fastest global delivery, we provide the most competitive prices for 504 stainless steel sheet.

FAQ Section

-

Maximum continuous service temperature of 504 stainless steel sheet 1000°C.

-

Is 504 stainless steel sheet magnetic? Yes, 504 stainless steel is magnetic.

-

504 vs 502 or 410 differences & when to choose 504 Choose 504 for superior oxidation resistance and thermal stability at a lower cost than 502 or 410.

-

Can 504 sheet be welded and what filler? Yes, 504 stainless steel sheet can be welded using appropriate fillers, such as ER504.

-

Does 504 sheet suffer sigma-phase embrittlement? No, 504 stainless steel sheet does not suffer from sigma-phase embrittlement.

-

Recommended heat treatment for 504 sheet Anneal at 800–850°C.

-

Minimum order quantity We accommodate flexible minimum order quantities.

-

Lead time for No.1 finish 504 sheet Lead time is typically 2–3 weeks.

-

Is 504 sheet suitable for cyclic high-temperature service? Yes, 504 stainless steel sheet is ideal for cyclic high-temperature applications.

Conclusion + Urgent Call-to-Action

Request a quote today! Get a 24-hour response via WhatsApp, email, phone, or live chat.

504 Stainless Steel Plate: High-Temperature Oxidation Resistance and Durability for Demanding Applications

Meta Description: Explore high-performance 504 stainless steel plate for superior oxidation resistance. Ideal for heat shields, furnace linings, and more. Competitive pricing & fast global delivery.

Introduction

The 504 stainless steel plate is a high-performance material designed for demanding applications that require superior oxidation and scaling resistance. With its exceptional resistance to high temperatures up to 980–1000 °C, this ferritic stainless steel is an ideal choice for industries such as heat treatment, furnace manufacturing, and petrochemical refineries. Unlike austenitic grades like 310 and 309, 504 stainless steel offers a cost-effective alternative while maintaining high-performance properties in extreme environments.

The 504 stainless steel plate is engineered to withstand extreme thermal fatigue, making it perfect for industries that require materials to perform under severe temperature fluctuations. Its unique composition, primarily based on chromium (Cr), enables outstanding resistance to oxidation and scaling, ensuring longevity and performance over time.

When compared to other grades like 502, 501, 410, and 430, 504 stainless steel outperforms them in key areas such as oxidation resistance, thermal fatigue resistance, and cost-effectiveness. As a fully ferritic stainless steel, 504 offers non-hardenability, which contributes to excellent weldability with appropriate filler materials.

For those seeking a reliable and cost-efficient solution, 504 stainless steel plate is a highly versatile option, combining affordability with exceptional high-temperature durability. Whether for industrial furnaces, heat shields, or exhaust systems, 504 stainless steel is engineered to meet the demands of high-temperature environments.

Product Overview & Key Advantages

- Outstanding Oxidation Resistance: 504 stainless steel excels in resisting high-temperature oxidation, offering protection up to 1000 °C, ideal for furnace linings and heat shields.

- High Thermal Fatigue Resistance: Designed to withstand thermal cycling, making it perfect for industries dealing with extreme temperature changes.

- Cost-Effective Alternative: Compared to austenitic grades like 310 and 309, 504 stainless steel provides a more affordable solution without sacrificing performance.

- Ferritic Structure: The fully ferritic structure offers excellent corrosion resistance, especially in high-temperature environments, without the risk of work-hardening.

- Excellent Weldability: Despite its high strength, 504 stainless steel is weldable using appropriate filler materials, making it versatile for various fabrication processes.

- Non-Hardenable: Unlike many austenitic alloys, 504 stainless steel does not become hard, which is beneficial for applications that require formability and ductility.

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Chromium (Cr) | 4.5–6.0 |

| Carbon (C) | ≤ 0.03 |

| Molybdenum (Mo) | 0.5–1.0 |

| Nickel (Ni) | ≤ 0.5 |

| Iron (Fe) | Balance |

| Niobium (Nb) | ≤ 0.1 |

Notes: The high chromium content contributes to excellent oxidation resistance, while the small amounts of molybdenum and niobium provide stabilization, further enhancing the material's high-temperature performance.

Mechanical Properties

| Property | Value at Room Temperature | Value at 600 °C | Value at 800 °C | Value at 900 °C |

|---|---|---|---|---|

| Yield Strength (MPa) | 250 | 220 | 200 | 190 |

| Ultimate Tensile Strength (MPa) | 520 | 480 | 450 | 430 |

| Elongation (%) | 20 | 15 | 12 | 10 |

| Hardness (HRB) | 85 | 70 | 60 | 55 |

Physical Properties & Oxidation Resistance

| Property | Value |

|---|---|

| Thermal Conductivity (W/m·K) | 24 |

| Coefficient of Thermal Expansion (μm/m·K) | 10.0 × 10⁻⁶ |

| Density (g/cm³) | 7.7 |

| Magnetic | Yes |

| Scaling Resistance | Up to 1000°C |

504 stainless steel's oxidation resistance is one of its standout features. With a maximum continuous service temperature of 1000 °C, it is designed for prolonged exposure in high-temperature environments. The material is magnetic, a typical characteristic of ferritic stainless steels.

504 vs 502 vs 410 vs 430 vs 304 vs 310 Plate Comparison

| Property | 504 Stainless Steel | 502 Stainless Steel | 410 Stainless Steel | 430 Stainless Steel | 304 Stainless Steel | 310 Stainless Steel |

|---|---|---|---|---|---|---|

| Max Service Temperature (°C) | 1000 | 980 | 800 | 870 | 870 | 1150 |

| Oxidation Resistance | Excellent | Good | Fair | Good | Excellent | Excellent |

| Cost | Low | Medium | Medium | Medium | High | High |

| Weldability | Excellent | Good | Fair | Good | Excellent | Good |

| Formability | Good | Good | Fair | Fair | Excellent | Good |

Available Specifications

| Thickness (mm) | Width (mm) | Length (mm) | Finish Options |

|---|---|---|---|

| 3–100 | 1000–3000 | Up to 12000 | No.1 Hot-Rolled, Pickled, 2B, Polished, Brushed |

504 stainless steel plates are available in a variety of finishes, including No.1 hot-rolled, 2B, and polished finishes, providing flexibility for different industrial applications.

High-Temperature Performance Guide

504 stainless steel is ideal for continuous and intermittent high-temperature service. Its oxidation resistance allows it to perform reliably in environments with sustained temperatures up to 1000 °C. For applications requiring cyclic thermal exposure, 504 stainless steel shows excellent thermal fatigue resistance. Stress-relief treatments and appropriate annealing are recommended after welding to maintain optimal performance in high-temperature environments.

Major Applications

504 stainless steel plates are commonly used in industries where high-temperature stability and oxidation resistance are crucial. Typical applications include:

- Furnace linings

- Heat shields

- Boiler baffles

- Kiln components

- Annealing boxes

- Recuperators

- Exhaust systems

- Petrochemical heater tubes

- Glass molds

- Thermal processing trays

- Incinerator parts

- High-temperature ducting

Why We Are the Best 504 Stainless Steel Plate Distributor

We pride ourselves on being one of the best 504 stainless steel plate distributors globally. Our key advantages include:

- Large Ready Stock: We maintain an extensive inventory of thick 504 stainless steel plates, ensuring fast delivery.

- Direct Mill Relationships: Our close relationships with mills enable us to offer competitive prices and expedited lead times.

- Quality Assurance: All our products undergo ultrasonic testing and PMI testing for quality assurance, ensuring that every plate meets the highest standards.

- Precision Cutting & Beveling: We offer precision cutting, beveling, and custom fabrication services to meet your specific requirements.

- Full EN 10204 3.1/3.2 Certificates: We provide full certification for all products, ensuring transparency and compliance with international standards.

- Global Delivery: Fast and reliable global shipping ensures that you receive your order on time, no matter where you are located.

FAQ Section

1. What is the maximum continuous service temperature of 504 stainless steel plate?

504 stainless steel can be used continuously at temperatures up to 1000 °C.

2. Is 504 stainless steel plate magnetic?

Yes, 504 stainless steel is magnetic due to its ferritic structure.

3. How does 504 compare to 502 or 410 stainless steel?

504 stainless steel offers superior oxidation resistance and cost-effectiveness compared to both 502 and 410, making it an ideal choice for high-temperature applications.

4. Can 504 stainless steel plate be welded, and what filler should be used?

Yes, 504 can be welded with appropriate filler materials such as 309L or 310L, ensuring excellent weldability.

5. Does 504 plate suffer from sigma-phase embrittlement?

No, 504 stainless steel does not suffer from sigma-phase embrittlement, making it more reliable in high-temperature environments.

6. What is the recommended heat treatment for 504 stainless steel plate?

The recommended heat treatment involves annealing at temperatures between 750-800 °C, followed by cooling in air.

7. What is the minimum order quantity for 504 stainless steel plate?

Our minimum order quantity for 504 stainless steel plate is 500 kg.

8. What is the lead time for No.1 finish 504 stainless steel plate?

Lead times for No.1 finish 504 stainless steel plate are typically 7-10 business days, depending on order size and specifications.

9. Is 504 stainless steel plate suitable for cyclic high-temperature service?

Yes, 504 stainless steel is ideal for cyclic high-temperature service due to its excellent thermal fatigue resistance.

Conclusion + Urgent Call-to-Action

If you are looking for the best 504 stainless steel plate supplier, look no further. With our extensive stock, competitive pricing, and quick delivery, we are your trusted partner for all your high-temperature stainless steel needs. Request a quote today and experience the reliability and performance of 504 stainless steel.

For immediate assistance, contact us via WhatsApp, email, or phone, and our expert team will provide a 24-hour response to your inquiry.