630 Stainless Steel Sheet & Plate: Premium Precipitation-Hardening Alloy

Meta Description: Discover 630 stainless steel sheet and plate with exceptional strength, superior fatigue resistance, and outstanding performance in high-stress applications. Available in various thicknesses and finishes.

Introduction

630 stainless steel sheet and plate are premium precipitation-hardening alloys that offer exceptional mechanical properties, making them ideal for high-stress applications where reliability and durability are paramount. Known for their high strength, good corrosion resistance, and superior fatigue resistance, 630 stainless steel sheets are widely used in aerospace, critical industrial equipment, and precision components.

The precipitation-hardening process allows 630 stainless steel to achieve exceptional strength while maintaining good corrosion resistance and machinability. This unique combination of properties makes 630 stainless steel sheets the preferred choice for applications requiring both high mechanical strength and long-term reliability.

Product Overview & Extreme Advantages

- Precipitation Hardening: 630 stainless steel sheets can be heat-treated to achieve exceptional strength levels, making them ideal for high-stress applications.

- High Strength: With yield strengths up to 1100 MPa after heat treatment, 630 sheets provide superior mechanical performance.

- Good Corrosion Resistance: 630 stainless steel offers excellent corrosion resistance comparable to 304 stainless steel, making it suitable for various environments.

- Superior Fatigue Resistance: The precipitation-hardening structure provides excellent fatigue resistance, ensuring long-term reliability in cyclic loading applications.

- Aerospace Grade Quality: 630 stainless steel sheets meet aerospace standards and are used in critical applications where failure is not an option.

- Excellent Machinability: Despite its high strength, 630 stainless steel maintains good machinability in the solution-annealed condition.

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Chromium (Cr) | 15.0–17.5 |

| Nickel (Ni) | 3.0–5.0 |

| Copper (Cu) | 3.0–5.0 |

| Niobium (Nb) | 0.15–0.45 |

| Carbon (C) | ≤ 0.07 |

| Iron (Fe) | Balance |

The 630 stainless steel sheets contain 15.0–17.5% chromium and 3.0–5.0% nickel, providing excellent corrosion resistance. The addition of copper and niobium enables the precipitation-hardening process, which significantly increases strength.

Mechanical Properties

| Property | Solution Annealed | H900 Condition | H1025 Condition | H1150 Condition |

|---|---|---|---|---|

| Yield Strength (MPa) | 450 | 1100 | 860 | 725 |

| Ultimate Tensile Strength (MPa) | 1035 | 1310 | 1170 | 1000 |

| Elongation (%) | 16 | 10 | 12 | 15 |

| Hardness (HRC) | 32 | 40 | 35 | 31 |

630 stainless steel sheets can achieve exceptional strength levels through heat treatment, with yield strengths up to 1100 MPa in the H900 condition. This makes them ideal for applications requiring both high strength and good corrosion resistance.

Heat Treatment

630 stainless steel sheets can be heat-treated to achieve different strength levels:

- H900: Aging at 900°F (482°C) for 1 hour, achieving maximum strength

- H1025: Aging at 1025°F (552°C) for 4 hours, providing balanced strength and toughness

- H1150: Aging at 1150°F (621°C) for 4 hours, offering good strength with improved toughness

630 vs 304 vs 316 vs 17-4PH Comparison

| Property | 630 Stainless Steel | 304 Stainless Steel | 316 Stainless Steel | 17-4PH Stainless Steel |

|---|---|---|---|---|

| Yield Strength (MPa) | 450–1100 | 205 | 205 | 725–1100 |

| Corrosion Resistance | Good | Excellent | Superior | Good |

| Heat Treatment | Precipitation hardening | None | None | Precipitation hardening |

| Fatigue Resistance | Excellent | Good | Good | Excellent |

| Cost | High | Medium | High | High |

630 stainless steel sheets offer superior strength compared to 304 and 316, while maintaining good corrosion resistance. They are comparable to 17-4PH but offer better machinability in the solution-annealed condition.

Available Types & Specifications

| Type | Sheet & Plate |

|---|---|

| Thickness | 0.5mm–100mm |

| Width | Up to 2000mm |

| Length | Up to 6000mm |

| Standards | ASTM A564, AMS 5643, UNS S17400 |

| Surface Finishes | 2B, BA, No. 4, No. 8, Custom |

630 stainless steel sheets are available in various thicknesses from 0.5mm to 100mm, with standard widths up to 2000mm and lengths up to 6000mm. We offer multiple surface finishes to meet specific requirements.

Major Applications

- Aerospace components

- High-stress structural applications

- Critical industrial equipment

- Precision components

- Oil and gas equipment

- Power generation components

- Automotive components

- Medical devices

- Defense applications

- Marine equipment

630 stainless steel sheets are used in industries where high strength, reliability, and durability are essential. Their exceptional mechanical properties make them ideal for critical applications where failure is not an option.

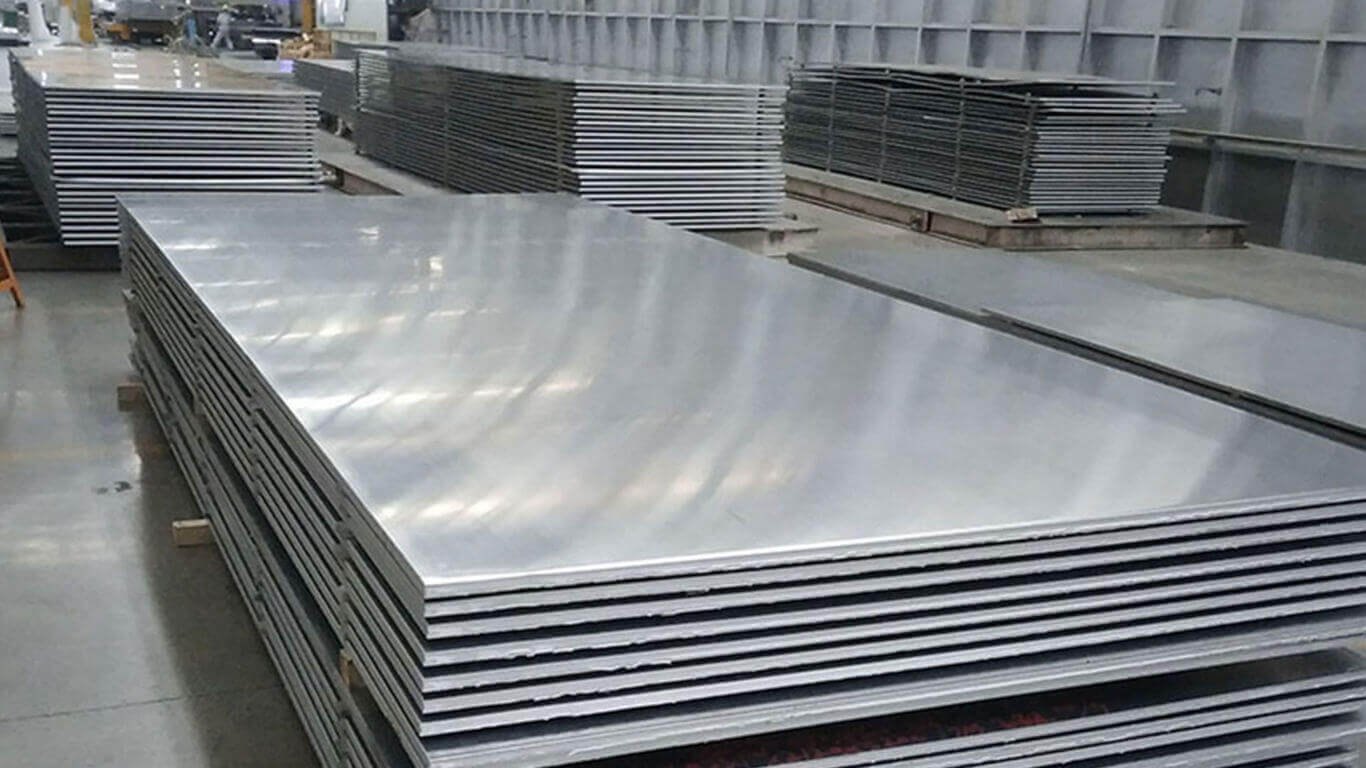

Product Images

Hot-rolled 630 stainless steel sheets ready for shipment

Professional infographic 630 stainless steel sheet data sheet + mechanical properties chart

Real-application collage – 630 sheets used in aerospace components, high-stress structural applications, and critical industrial equipment

Why We Are the Best 630 Stainless Steel Sheet Distributor

As the leading global supplier of 630 stainless steel sheets, we provide:

- Largest stock of premium 630 sheets for immediate delivery

- Direct mill contracts, ensuring the best prices and availability

- In-house heat treatment capabilities for custom strength requirements

- 100% quality testing, ensuring superior quality control

- Full certification package with each shipment

- Custom cutting & machining to meet your specific needs

- Fastest worldwide delivery with unbeatable prices

Packaging & Quality Assurance

We ensure the safe delivery of 630 stainless steel sheets with:

- Heavy wooden cases and steel cradles for protection

- Protective film to prevent surface damage

- Full certification package, including material traceability and test reports

FAQ Section

Q: What is the maximum strength achievable with 630 stainless steel?

A: 630 stainless steel sheets can achieve yield strengths up to 1100 MPa in the H900 condition.

Q: Is 630 stainless steel magnetic?

A: Yes, 630 stainless steel is magnetic in all heat-treated conditions.

Q: Can 630 stainless steel be welded?

A: Yes, 630 stainless steel is weldable, but it requires proper preheat and post-weld heat treatment to maintain properties.

Q: What is the difference between 630 and 17-4PH?

A: 630 and 17-4PH are essentially the same alloy (UNS S17400), with 630 being the newer designation.

Q: What heat treatment is recommended for maximum strength?

A: H900 condition (aging at 900°F for 1 hour) provides maximum strength for 630 stainless steel sheets.

Conclusion + Urgent Call-to-Action

For instant quotes on 630 stainless steel sheets, contact us 24/7 via WhatsApp, email, phone, or live chat. Trust the best supplier for your high-strength sheet needs.