640 Stainless Steel Sheet: Precipitation-Hardening Strength with Superior Corrosion Resistance

Meta Description: Discover 640 stainless steel sheet offering up to 1350 MPa strength, superior corrosion resistance vs 17-4PH, ideal for aerospace, oil & gas, and medical applications.

Introduction

640 Stainless Steel Sheet (UNS S15500) is a high-performance precipitation-hardening martensitic stainless steel that delivers exceptional strength and superior corrosion resistance compared to 17-4PH stainless steel. This versatile material is a preferred choice in critical industries like aerospace, oil & gas, medical, and nuclear applications, where both high strength and corrosion resistance are non-negotiable.

With a yield strength reaching up to 1350 MPa, 640 stainless steel sheet is designed for heavy-duty applications requiring maximum durability under high-stress and high-temperature conditions. It offers enhanced resistance to pitting, stress corrosion cracking, and general corrosion, especially in chloride-rich environments. This makes it an ideal candidate for valve bodies, turbine blades, medical instruments, and oil & gas downhole tools.

Compared to 17-4PH stainless steel, 640 stainless steel provides higher corrosion resistance, which is crucial in harsh environments like seawater, chemical processing, and high-pressure conditions. Its precipitation-hardening process allows it to achieve high strength while retaining excellent fatigue resistance and machinability in the annealed condition. Whether you’re looking for 640 stainless steel plate or sheet, we offer the best pricing and fast global delivery.

Product Overview & Key Advantages

- Exceptional Strength: 640 stainless steel sheet delivers a yield strength up to 1350 MPa, making it ideal for aerospace, medical, and high-pressure industrial applications.

- Superior Corrosion Resistance: Offers better resistance to pitting, stress corrosion cracking, and general corrosion compared to 17-4PH and 630 stainless steel.

- Martensitic Structure: The martensitic structure provides excellent fatigue performance, particularly in demanding dynamic loading conditions.

- Precipitation Hardening: 640 stainless steel can be heat-treated to different aging conditions like H900, H925, H1025, H1150, and H1150M, providing the flexibility to meet various performance requirements.

- Machinability: Easy to machine in the solution annealed condition while still achieving high strength after aging.

- Versatile Applications: Widely used for aerospace structural parts, oil & gas downhole tools, medical implants, turbine components, high-strength fasteners, and nuclear reactor parts.

- Global Availability: We are a leading 640 stainless steel sheet supplier with large stock holdings and the fastest delivery worldwide.

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Chromium (Cr) | 14.0–15.5 |

| Nickel (Ni) | 3.5–5.5 |

| Copper (Cu) | 2.5–4.5 |

| Niobium (Nb) | 0.15–0.45 |

| Tantalum (Ta) | 0.15–0.45 |

| Carbon (C) | ≤ 0.07 |

| Manganese (Mn) | ≤ 1.0 |

| Silicon (Si) | ≤ 1.0 |

| Phosphorus (P) | ≤ 0.04 |

| Sulfur (S) | ≤ 0.03 |

| Iron (Fe) | Balance |

The 640 stainless steel composition is primarily characterized by high chromium content (14.0–15.5%) for excellent corrosion resistance and nickel (3.5–5.5%) for toughness and ductility. Copper (2.5–4.5%) enhances its corrosion resistance, while niobium and tantalum ensure precipitation hardening and stability at high temperatures. The low carbon content reduces the risk of carbide precipitation, ensuring structural integrity during welding.

Mechanical Properties

| Condition | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | Hardness (HRC) |

|---|---|---|---|---|

| Solution Annealed | 600 | 1000 | 20 | 25–30 |

| H900 | 900 | 1150 | 10 | 35–40 |

| H925 | 925 | 1200 | 8 | 38–42 |

| H1025 | 1025 | 1300 | 6 | 40–44 |

| H1150 | 1150 | 1400 | 5 | 42–46 |

| H1150M | 1150 | 1400 | 5 | 44–48 |

640 stainless steel sheet exhibits exceptional strength across various heat treatment conditions. The H900 and H925 conditions offer significant yield strength, making it ideal for aerospace and high-performance components. The H1150M condition achieves the highest strength and hardness (up to 48 HRC), ideal for applications requiring maximum strength in high-temperature environments.

Physical Properties

| Property | Value |

|---|---|

| Density (g/cm³) | 7.80 |

| Thermal Conductivity (W/m·K) | 16.5 |

| Specific Heat (J/kg·K) | 460 |

| Electrical Resistivity (Ω·cm) | 0.00074 |

| Magnetic (after hardening) | Yes |

The density of 640 stainless steel is 7.80 g/cm³, typical of high-strength materials, while its thermal conductivity is 16.5 W/m·K. This allows it to maintain its strength at elevated temperatures. After hardening, 640 stainless steel becomes magnetic, which is an important consideration for certain industrial applications.

640 vs 630 vs 17-4PH vs 304 vs 316 vs 17-7PH Sheet Comparison

| Property | 640 Stainless Steel | 630 Stainless Steel | 17-4PH Stainless Steel | 304 Stainless Steel | 316 Stainless Steel | 17-7PH Stainless Steel |

|---|---|---|---|---|---|---|

| Yield Strength (MPa) | 1350 | 1200 | 1100 | 250 | 290 | 1100 |

| Corrosion Resistance | Excellent | Good | Excellent | Good | Excellent | Excellent |

| Hardness (HRC) | 35–48 | 30–42 | 38–44 | 20–30 | 25–35 | 38–42 |

| Heat Treatment | H900, H925, H1025, H1150 | Solution Annealed | RH950, CH900 | Annealed | Annealed | RH950, CH900 |

| Cost | Moderate | Moderate | Moderate | Low | High | Moderate |

When compared to 17-4PH and 630 stainless steel, 640 stainless steel excels in strength and corrosion resistance. While 316 stainless steel offers superior corrosion resistance, it cannot match the strength of 640. 17-7PH and 640 share similarities in performance, but 640 is ideal when higher strength is required.

Available Specifications

| Thickness (mm) | Width (mm) | Length (mm) | Finish Types |

|---|---|---|---|

| 0.5–100 | 1000–2500 | Up to 12000 | 2B, No.1 Hot-rolled, Pickled, Polished, Brushed |

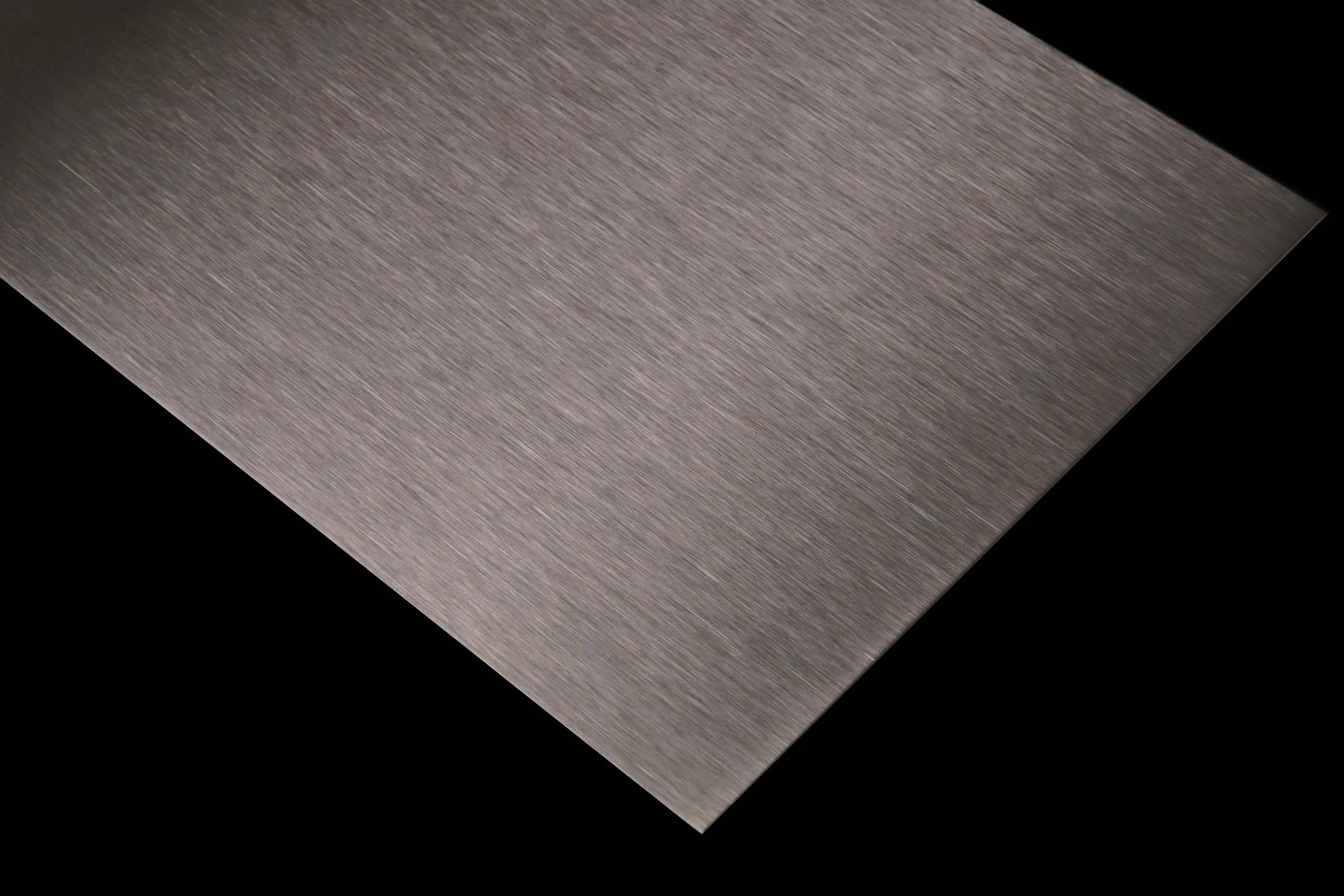

Our 640 stainless steel sheet is available in thicknesses ranging from 0.5 mm to 100 mm, with widths up to 2500 mm and lengths up to 12 meters. It comes in various finishes, including 2B, No.1 hot-rolled, pickled, polished, and brushed, allowing you to choose the finish that best suits your requirements.

Heat Treatment & Precipitation Hardening Guide

640 stainless steel undergoes solution annealing at 1038°C to optimize its mechanical properties. The material can then be aged in various conditions (H900, H925, H1025, H1150, and H1150M) to achieve the desired strength and hardness, ranging from 28 HRC to 48 HRC.

Major Applications

- Aerospace structural parts

- Turbine blades

- Pump shafts

- Valve bodies

- Medical instruments

- Oil & gas downhole tools

- Nuclear reactor components

- High-strength fasteners

- Surgical tools

- High-pressure vessels

640 stainless steel sheet is widely used in aerospace, medical, and oil & gas applications, offering excellent performance in high-temperature and high-pressure environments.

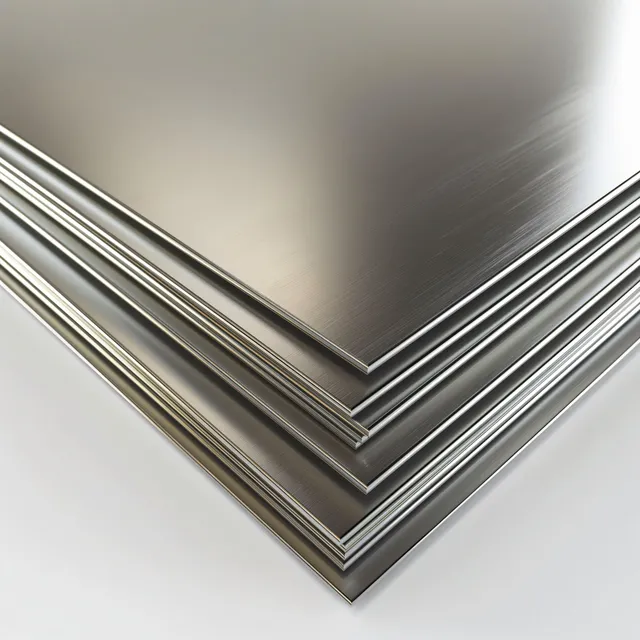

Product Images

Hot-rolled 640 stainless steel sheets ready for shipment

Professional infographic 640 stainless steel sheet data sheet + mechanical properties chart

Real-application collage – 640 sheets used in aerospace components, turbine blades, and medical instruments

Why We Are the Best 640 Stainless Steel Sheet Distributor

As a trusted 640 stainless steel sheet supplier, we offer large ready stocks in all conditions, from solution annealed to H1150M. With direct mill relationships, precision cutting, and ultrasonic testing, we guarantee the fastest delivery, 100% quality assurance, and the most competitive pricing.

FAQ Section

-

What is the maximum hardness of 640 stainless steel sheet?

- 44–48 HRC depending on the aging condition.

-

Is 640 stainless steel sheet magnetic after hardening?

- Yes, it becomes magnetic after hardening.

-

640 vs 17-4PH differences & when to choose 640?

- 640 offers higher strength and better corrosion resistance compared to 17-4PH.

-

Can 640 sheet be welded and what filler?

- Yes, it can be welded using 15-5PH filler wire.

-

Recommended aging condition for maximum strength?

- H1150M provides the maximum strength.

-

Corrosion resistance in seawater or chloride environments?

- 640 stainless steel offers excellent resistance to corrosion in these environments.

-

Minimum order quantity?

- Please contact us for custom orders and MOQ details.

-

Lead time for H900 condition 640 sheet?

- 4–6 weeks depending on stock and quantity.

-

Is 640 sheet suitable for cryogenic applications?

- Yes, it retains good strength at low temperatures.

Conclusion + Urgent Call-to-Action

Request a quote today for 640 stainless steel sheet with 24-hour response. Contact us via WhatsApp, email, phone, or live chat for immediate assistance.