200 Series Stainless Steel Uses

Kitchenware & Appliances

Cookware, kitchen sinks, and home appliances.

Automotive

Exhaust systems, body parts, and engine components.

Architecture

Structural components, cladding, and building facades.

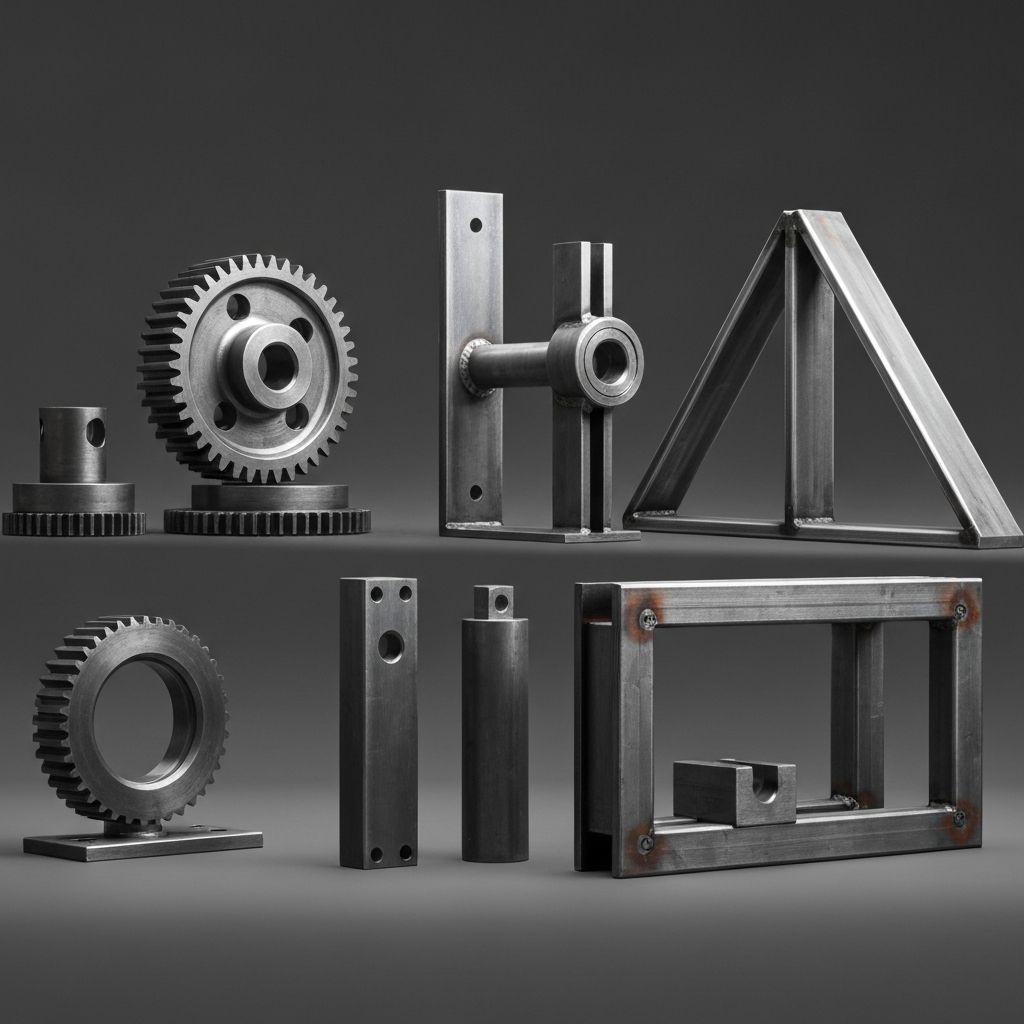

Industrial Equipment

Pipes, fittings, and components for machinery and equipment.